Mainetti, one of the world’s leading hanger manufacturers, contributes to sustainable transformation in the clothing industry with the steps it takes to recycle, embrace the use of renewable energy and reduce the use of virgin plastic. The company, announcing its Full Circle global sustainability and operations strategy by publishing its sustainability targets for 2025 and beyond, emphasizes concrete steps to be taken and collaborations in this context, as well as targets. Full Circle will define how the company operates going forward, including decarbonizing operations, promoting the circular economy, and ensuring safe and efficient operations for the whole workforce. This initiative is built on the success of the group’s Plan M, launched in 2012, establishing Mainetti as a ‘sustainability first’ company.

Mainetti Chief Operations Officer Keith Charlton stated that the achievements in the last nine years of Plan M have been excellent in establishing Mainetti as a ‘sustainability first’ company. She remarked that they are now excited to build upon these foundations through the ambitious Full Circle Initiative targets they have set themselves for the next four years and beyond, saying; “Our innovations in sustainability and circular economy processes and practices assist our customers in meeting their own circular economy targets for plastics. Full Circle is good for business and good for the environment.”

Mainetti aims to use 100 percent renewable energy by 2030

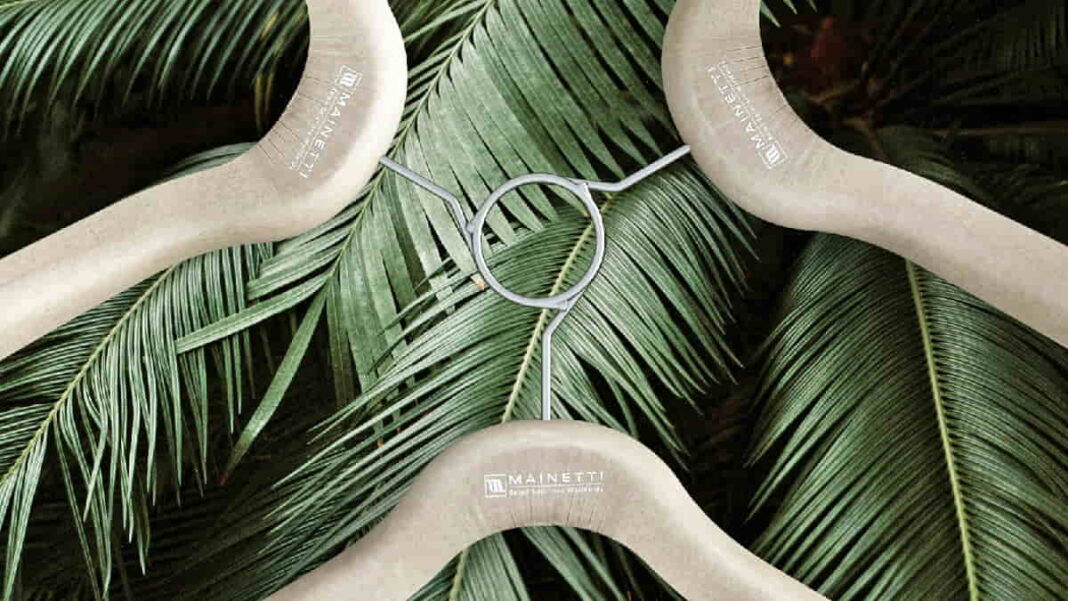

Mainetti takes a phased approach to decarbonizing its business, using as little energy sourced from non-renewable fossil fuels. The company has been reducing its carbon footprint and increasing energy efficiency in its operations since 2012, and utilizes Energy Attribute Certificates, switching to on-site or grid-sourced renewable electricity where possible. Currently, 61% of the energy used by the group is renewable with the aim of increasing this to 80% by 2025 and 100% by 2030. Mainetti, by promoting the circular economy, will introduce and expand a wider range of products made from renewable sources such as paper, card or compostable materials and reduce the use of virgin plastic as far as possible.

The company realized the demand for sustainable packaging in the Near East and significantly increased the capacities of its existing hanger and flexible packaging factories in Türkiye in 2021, expanding it to 14.000 m2 to meet the needs of brands it works with in the retail sector. Türkiye meets the demand of regional and international brands to offer sustainable packaging solutions to their customers due to its strategic location in the Middle East and proximity to leading retailers in Europe.

Polyloop offers retailers a truly circular economy

Increasing demand for recycled plastic is causing soaring prices and good quality recycled plastics cost very close to the price of virgin. Mainetti states that one way of solving the issue of the limited supply of recycled plastic is for companies to invest in their own facility or technology. In 2021, the company launched Mainetti Polyloop, the world’s first global initiative that allows retailers to implement a closed-loop clear polythene recycling system, offering retailers a truly circular economy. It also offers the opportunity to source clear LDPE film containing at least 30 percent post-consumer recycled material from any production site in the world.

Post-consumer LDPE film is collected, cleaned, and processed within the UK before being distributed to Mainetti’s manufacturing sites around the world. Polyethylene film cleans any print and label due to the diversity of this recycling process, providing the highest level of clarity for post-consumer recycled content. Polyloop has the capacity to process 4 thousand tons of recycled materials per year.

Mainetti, leading the industry in the reuse and recycling of clothes hangers, has implemented circular practices and offers innovative and sustainable solutions to its customers with 6000 employees in 46 locations in 6 continents. The company’s portfolio includes Hangers, Accessories, Labels, Flexible Packaging, Structural Packaging Products, Branding, Supply Chain, Intelligent (RFID) Solutions and Health and Safety products.