Scientists have succeeded in obtaining powder dye by growing the indigo plant (Indigofera tinctoria), which can be used instead of synthetic dyes in the textile industry and is cultivated in tropical countries, for the first time in Türkiye, Antalya. Instructor at Akdeniz University Faculty of Agriculture, Department of Field Crops, Prof. Dr. Kenan Turgut and his team, carrying out their studies at Güney Agripark R&D Company within the scope of TÜBİTAK TEYDEB Project, have achieved successful results on their way to take a step towards reducing environmental pollution caused by textile dyeing by producing indigo dye in Türkiye.

Approximately 800 thousand tons of synthetic dyes are produced annually worldwide, of which approximately 75 percent are used in the textile industry. While the discharge of textile wastewater containing synthetic dyes without treatment causes environmental pollution, the preference of natural dyes in the textile industry is important both from the perspective of preventing environmental pollution and the effective use of limited water resources.

“It is suitable for cultivation in the Mediterranean climate”

Kenan Turgut, who spoke to AA reporter, stated that seeing there was a deficit in the textile industry and natural dyeing, they started their research considering that Türkiye could have potential in this regard. Noting that indigo is suitable for growing in the Mediterranean climate as it is a tropical plant, Turgut shared the following information about the process of growing the plant:

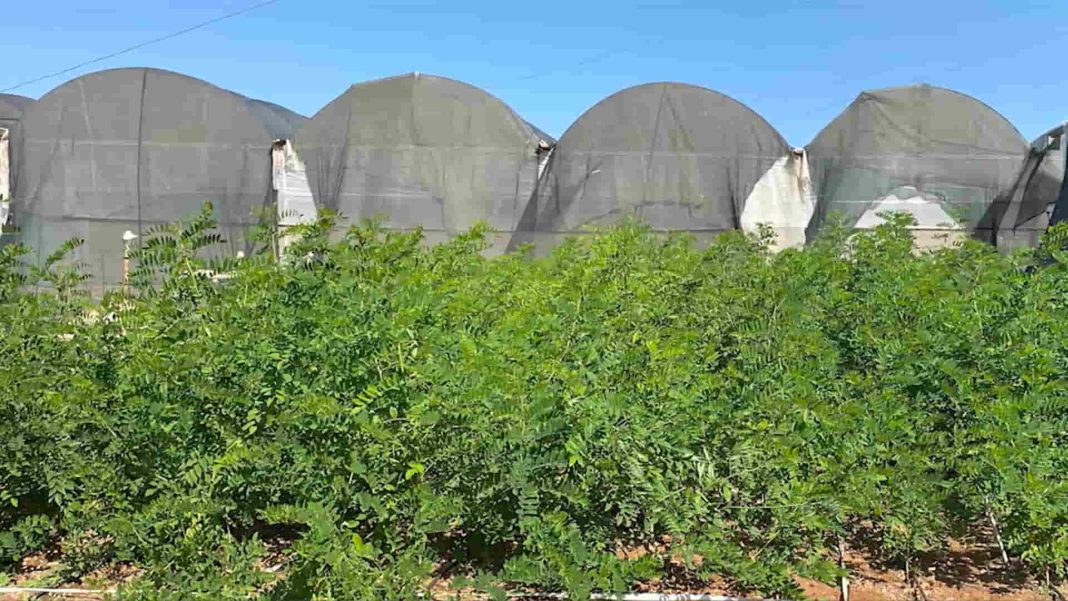

“First, we had to germinate the seeds to start tissue culture and we got our first plants from them. There were 10-12 plants that we planted. Actually, 2-3 plants are enough for tissue culture. It is possible to produce tens of thousands of plants from them within a year. It has such a feature, so we call micropropagation rapid production. After we obtained those plants and the plants reached the seedling stage, tissue culture was immediately activated. We obtained many thousands of plants from there, and we established our trials in the field with those plants. Last year we took our first leaf samples.”

20-25 kilograms of indigo powder dye can be obtained from 2-2.5 tons of product

Giving information about the yield they obtained from the plant during the R&D process, Kenan Turgut said: “Approximately 2-2.5 tons of product can be obtained from 1 decare and 20-25 kilograms of indigo powder dye can be obtained.” Turgut explained the details of the process of obtaining blue dye from indigo as follows: “You need to have a mixing and ventilation system and keep it in a closed environment with high PH for a few days, then it will solidify after a certain period of time and turn it blue in that process. After we get this indigo color, we get a blue, solid substance. Then it needs to be crumbled into powder.”

“Only 1 percent of dyes used in the world textile industry is natural”

Drawing attention to the fact that only 1 percent of the dyes used in the global textile industry are natural dyes, Kenan Turgut emphasized that the use of natural dyes in the textile industry, which is the second most polluting sector in the world, should become widespread in order to make proper use of limited water resources. Turgut continued his words as follows:

“When we compare natural dyes with chemical dyes, they have important advantages. One of them is that they are healthy, the second is that they give high fastness, what we call high here is resistant to washing and light. The third is that they have a long service lifespan. I think this is very important in the textile industry. The fourth is that they are non-toxic and non-allergenic. The fifth is that they are eco-friendly. Therefore, when we bring these together, we realize how late the world is in this regard.”

Stating that they will continue the breeding studies of the plant in the following process and continue production by selecting and reproducing good plants, Turgut concluded his words as follows: “Our main purpose is textile, but natural dyes can also be used as food coloring. In addition, natural dyes are also used in cosmetics, pharmaceutical industry, hobbies and handicrafts. They are more common especially in Europe and America. Therefore, that market is also very important. So, the area of use is actually much wider.”