Itema, one of the reliable partners of the textile industry for weaving machines and integrated textile services, met with numerous textile professionals from all over the world at ITMA 2023 and further strengthened its ties with the industry. The Itema booth, consisting entirely of weaving machines belonging to the new EVO range, inspired the visitors for more sustainable and innovative production models. Itema Türkiye General Manager Pamir Özaltan talked to Textilegence about their experiences and impressions of the exhibition.

Stating that ITMA 2023 is an important meeting point for the entire textile industry after the pandemic period, Özaltan said that they observed a significant increase in the number of visitors compared to ITMA 2019 in Barcelona. He said that they hosted more than 1000 companies at their booth, with Türkiye as one of the main countries of origin for visitors, where weavers had the opportunity to get to know not only the weaving machines portfolio but also the complete range of solutions offered by Itema.

Özaltan commented that Itema since ever focuses on innovation as the mission to provide the market with valuable solutions and said: “Itema is the only company in the industry featuring a stand-alone company entirely dedicated to innovation: Itemalab. With a team of approximately 70 engineers, Itemalab works on innovative projects by evaluating and prioritising the demands received by the market. In this direction, we focused on four main points at ITMA 2023. The first of these is eco-efficiency, to provide more benefits to both weavers and planet with a more sustainable production while at the same time reducing production costs, the second is to further enhance textile mastery to unleash our customers creativity and ensuring maximum textile versatility. Easy weaving is also the Itema vision to maximize the weaver experience when working on the machine, thus reducing machine downtime, and simplifying daily operations. Last but not least, digitalization is a must to optimize processes and productivity.”

Itema offers new opportunities with the new EVO weaving range

Pamir Özaltan, stating that they introduced the new EVO weaving portfolio for the first time at ITMA 2023, added that 7 of them were exhibited at Itema booth and 5 of them were exhibited at the booths of their partners Stäubli, Van De Wiele, MEI and Julibao. Noting that the name EVO comes from ‘evolution’ and in this sense, it represents the new stage reached by the Itema technology, Özaltan explained that the EVO series further enlarge the yarn type and range using in the weft transfer to maximize the already well-known Itema textile mastery. He also mentioned that they have made some innovations to improve the user experience and production processes and disclosed: “We continue to provide more benefits to our customers with our new Itema weaving mill monitoring system MyWeave. Moreover, we also launched iKNOW, a new software which acts as a library of fabric styles where the weaver can find, save, restore weaving and machine parameters thus significantly reducing machine set up operations.”

He said that the new EVO range of rapier and airjet weaving machines, also features a new machine terminal and electronic infrastructure. Özaltan disclosed: “The console of the EVO series provides remote control to customers through WiFi and Bluetooth connection. The EVO electronic platform is even more powerful of its predecessor, thus establishing a new benchmark in the market.”

Weavers achieve sustainable weaving with iSAVER®

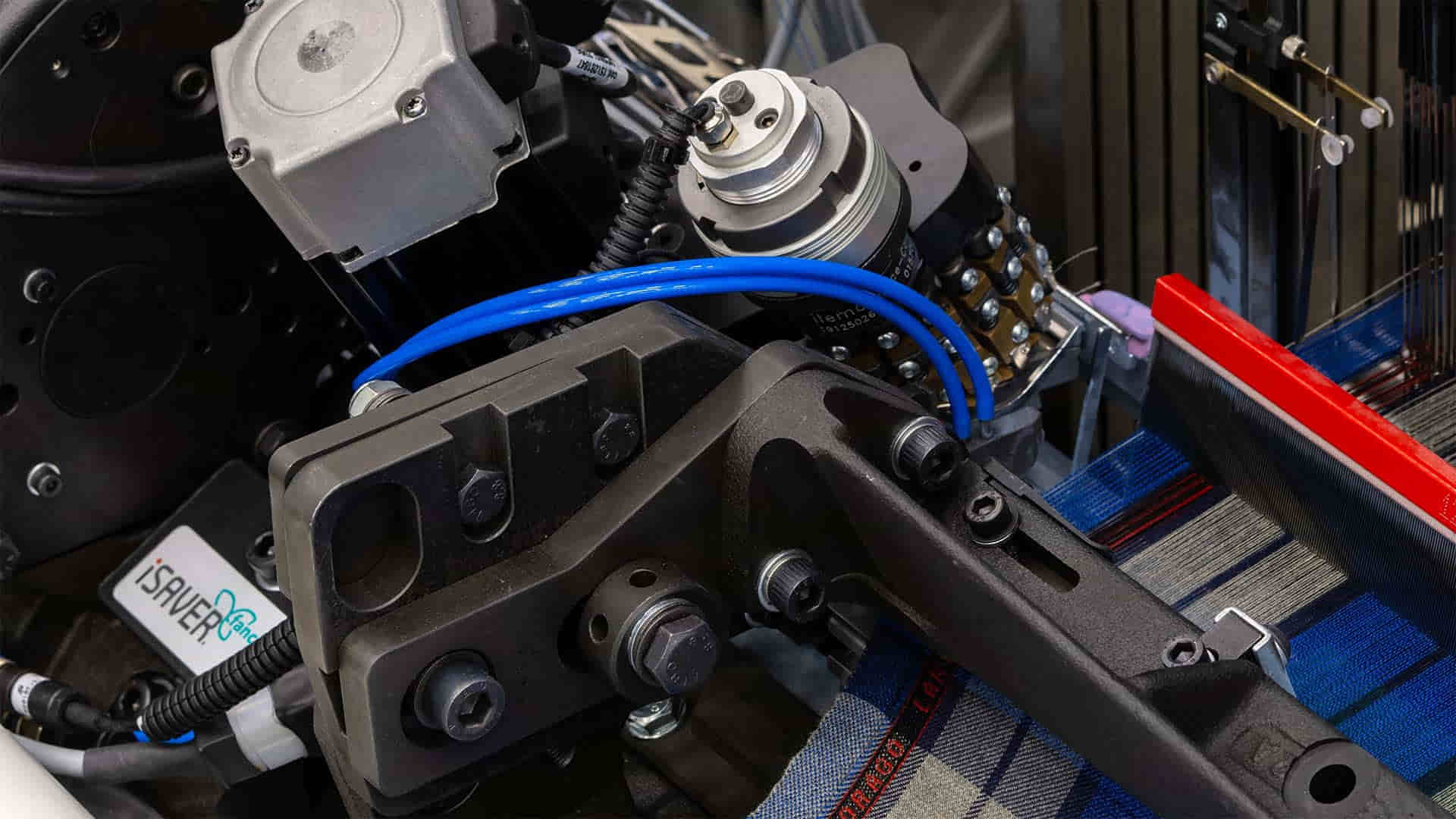

Pamir Özaltan reminded that Itema first introduced the iSAVER®, which made a revolution in the denim market by eliminating one of the selvedge wastes in rapier weaving, at ITM 2018 in Istanbul, and noted that this technology has been further developed for ITMA 2023. He continued his words as follows:

“In rapier weaving technology, a total of approximately 12-14 cm of weft waste occurs on the left and right sides, depending on the weft type. In 2018, after the iSAVER, which eliminates the left side waste with a mechatronic technology, was introduced to the market, we further developed it and made it available to weavers in 3 different versions in 2023. iSAVER is one of the most innovative and environmentally friendly technologies in recent history in the weaving industry and plays a considerable role in sustainable production. We recommend iSAVEReco, especially in cotton and denim production. At ITMA 2023, we launched the iSAVERfancy that, up to 6 weft colors, is ideal in the production of sophisticated fabrics, such as wool and worsted, and cashmere, and the iSAVERtech which is dedicated to the production of a wide range of technical textiles. Today iSAVER represents the only reliable innovation capable to contributing to a sustainable weaving, we started in 2018 with denim and we can now offer the same, mature technology for the benefit of other textile productions.”

Say greetings to the Itema World with ‘HelloItema’

Finally, Pamir Özaltan invited his customers to register to the new Itema customer portal HelloItema via hello.itemagroup.com and concluded his words as follows: “This way, all our customers will be able to follow their machine parks, service requests for each machine, spare parts requests and orders from a single portal and from any personal computer or iOS / Android operating system devices and cloud environment. Optionally, if configured in the membership package, it will even be possible to access the Itema advanced weaving mill monitoring system MyWeave and the textile library iKNOW, which includes a set of ideal initial setting conditions for Itema weaving machines.”