Asteks is the leader in the Turkish textile market with their cots & aprons and cots grinding machine solutions, and expands its claim to the regional markets with the same faith and hard work will. Providing solutions to several reputable manufacturers of growing textile markets, Asteks has become a preferred brand in the markets with prestigious references. Nishat Group, one of the biggest business corporation in Pakistan, chose Asteks as their partner for cots grinding solutions.

Nishat Group

Nishat Group has a significant scale in the business world of Pakistan, and is branched through several industries, as well as textile. Having a vertical integrated structure in their main business textile, the group has a considerable production power and capacity in spinning, weaving and sewing facilities. Nishat Mills Limited, one of the group’s companies that have been producing yarn since 1951, exported 353.03 million dollars in 2018. Nishat Mills Ltd. consists of 8 spinning mills, and currently has a total capacity of 250 thousand spindles and a daily spinning capacity of 200 tons of cotton and blended yarns.

The installation of the Asteks’ 201-SF cots grinding machine with smart feeding system at Nishat Mills Ltd. in Faisalabad was completed at the end of 2018 and the machine started up with superior performance. Nishat Mills Ltd. started to work with Asteks in 2017 with cots & aprons products. The company officials had the opportunity to closely examine Asteks’ machinery at ITM Istanbul in 2018. The cots grinding machines, what are the result of transfer of Asteks’ experience in cots manufacturing, attracted their attention with their stunning performances. Establishing confidence in the machine through the detailed technical studies they have carried out, the company has decided to make the investment of their new cots grinding machine by Asteks.

“We have obtained a cots grinding solution that has met our expectations”

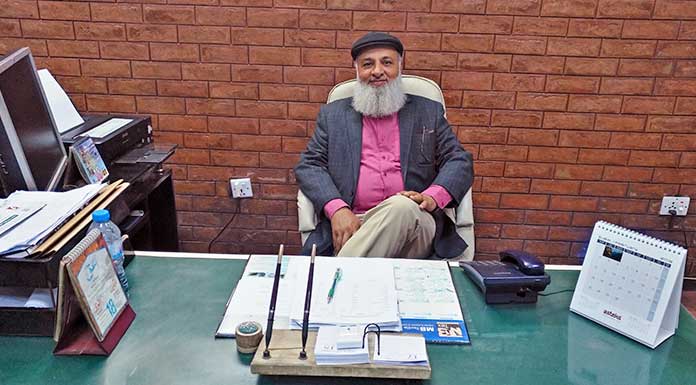

Nishat Mills’ 6th and 7th Plant General Manager Sardar Mehmood Akhtar said that the 201-SF cots grinding machine has been one of their most important aides since it was installed, with its trouble-freeness, reliability and user-friendliness. Akhtar said; “We have introduced a new investment scheme, as the current manual grinding machine in our plant is unable to respond to the needs of our developing production power. Asteks has a very long experience in cots processing. The new generation 201-SF cots grinding machine with smart feeding system has convinced us with its features and strength and we went with the investment”.

Mr. Akhtar added that 201-SF contributes to the production process due to its user-friendliness and low maintenance requirement; and underlined that the quality of the machine is equivalent to those of European machines. “We preferred 201-SF not only because of the machine itself; but because there is a well experienced and reliable manufacturer behind it,” said Mr. Akhtar; and continued saying that since the installation, the service they have received and the performance they have achieved; show that they made the right decision in the investment. Sardar Mehmood Akhtar; “In line with the success we achieved with the 201-SF cot grinding machine that meets all our needs, I can recommend it to other textile companies within the Group as well as to the textile companies out of the Group”.

We have built up a strong reference in the Pakistani market with Nishat Group

Asteks Export Markets Sales Manager Taner Engin said that the textile manufacturers in developing markets have great importance for them. After the successful commissioning of one 201-SF machine in Nishat Mills 6th and 7th mills; Engin announced their machines found place in two new projects thanks to that reference.

Taner Engin pointed out that the Pakistani market is rapidly developing in textiles; and emphasized that their machine’s successful high performance in one of the most reputable players of this export market is a very prestigious reference for them. Engin; “Our machine in Nishat Mills Ltd. has become a remarkable reference for us while promoting our products in Pakistani market. We have also seen its successful reflections at IGATEX 2019. Together with our local partners, we are able to reach Pakistani textile manufacturers more easily”.

Advantages of 201-SF, cots grinding with smart feeding system

Several textile manufacturers, especially Nishat Mills Ltd., achieve high efficiency with the new features of 201-SF. Along with user-friendly, high precision process quality and low maintenance, the smart feeding system increases operation efficiency. With manual cots grinding systems, an employee must feed each cot individually in the magazine cassette. So this means that an employee must allocate a large portion of their work schedule to the feeding process. In 201-SF, the cots are poured into the feeding boxes in bulk quantity at once. The smart feeding system aligns these cots to the magazine cassette to be delivered to the grinding section; without labour required.

Another automation is offered by 201 SF; in conventional systems, cots with different diameters are manually measured by an employee with a calliper. This means additional labour and a loss of time in classification and separation. 201-SF does the outer diameter measurement of these cots with a laser diameter measurement system. Minimum and maximum value input is sufficient by the operator. The cots not in this specified range are separated before being sent to the grinding section. Only the cots in the specified diameter range are delivered to the grinding section.

Not necessary to completely dismantle the upper structure of the machine

In addition to all types of short cots for ring spinning and roving frames; long cots such as draw frame and combing frame cots can be grinded on 201-SF; with no need of an additional system, a complicated modification or time-consuming conversions. Unlike with conventional systems; it is not necessary to completely dismantle the upper structure of the machine; and to place the new stone to grind the long cots for draw frame and combing frames. This adequate and fast system allows for a variety of features and functionality; while long-term machine downtime is avoided. This simplified operation and ease of maintenance are vital for total efficiency.

The 201-SF cots grinding machine is currently being operated at Nishat Mills at 350 top rollers per hour (700 cots) of grinding speed; and meets all requirements. Depending on the operating conditions; the 201-SF also offers solutions to the more advanced requirements of the yarn manufacturers with higher speeds.