Oerlikon’s Polymer Processing Solutions division and its joint venture partner BB Engineering will once again be taking part at ITM 2024, Türkiye’s most important textile machinery exhibition, on June 4-8. The machine and system manufacturer Oerlikon will be presenting visitors with complete solutions from melt to yarn, fibers and nonwovens. The experts from both companies will be providing information about their sustainable machines and system technologies at the Tekstil Servis in Stand 706 in Hall 7.

Oerlikon Sales Director Oliver Lemke said: “Our customers are showing great interest in factory projects, which include everything from in-house polycondensation systems to texturized yarn and corresponding digital solutions. From melt to yarn and beyond, indeed.” The supply of all process steps from a single source promises harmonised technology, the design of which ensures the high quality of the yarn produced.

Oerlikon to offer its sustainable concepts at ITM

Another important topic the company will focus on at ITM 2024 will be sustainability. There is a lot going on in manmade fiber yarn production in particular: mechanical and chemical technologies for recycling bottles, but also textiles, biopolymers, circular economy – all of this is no longer a thing of the future. With partners and subsidiaries such as Oerlikon Barmag Huitong Engineering (OBHE) and Barmag Brückner Engineering (BBE), Oerlikon Polymer Processing Solutions is presenting concrete concepts here.

Oerlikon to once again be focussing on the topics of energy, economics, environment and ergonomics at ITM, will also celebrate e-save’s 20th anniversary. Oerlikon Textile Head of Marketing, Corporate Communications and Public Affairs André Wissenberg stated that profitable and sustainable growth for everyone involved is the goal of the company and therefore also their contribution to securing a sustainable future, saying: “Performance, quality, sustainability and commitment are the factors that enable our division to face the challenges of the future with confidence every day. With the constant expansion of our e-save philosophy, we are continuously creating and increasing value with high-quality and innovative solutions for the entire textile industry.”

Recycling is the future

OBHE’s homogenisation technology stands for the mechanical recycling of processed polyester (PET) waste such as post-industrial waste (popcorn), bottle flakes and film. The Oerlikon Barmag homogenizer ensures a uniform, homogeneous melt, influences the viscosity increase and thus makes it possible to produce defined rPET pre-products for further processing, such as melt, flakes or fiber material for direct spinning. The first plants have already been successfully commissioned worldwide.

Another rPET solution is the VacuFil system from BB Engineering. VacuFil is a unique and innovative PET recycling system that combines gentle large-scale filtration and targeted regulation of the intrinsic viscosity (IV) for consistently excellent rPET melt quality.

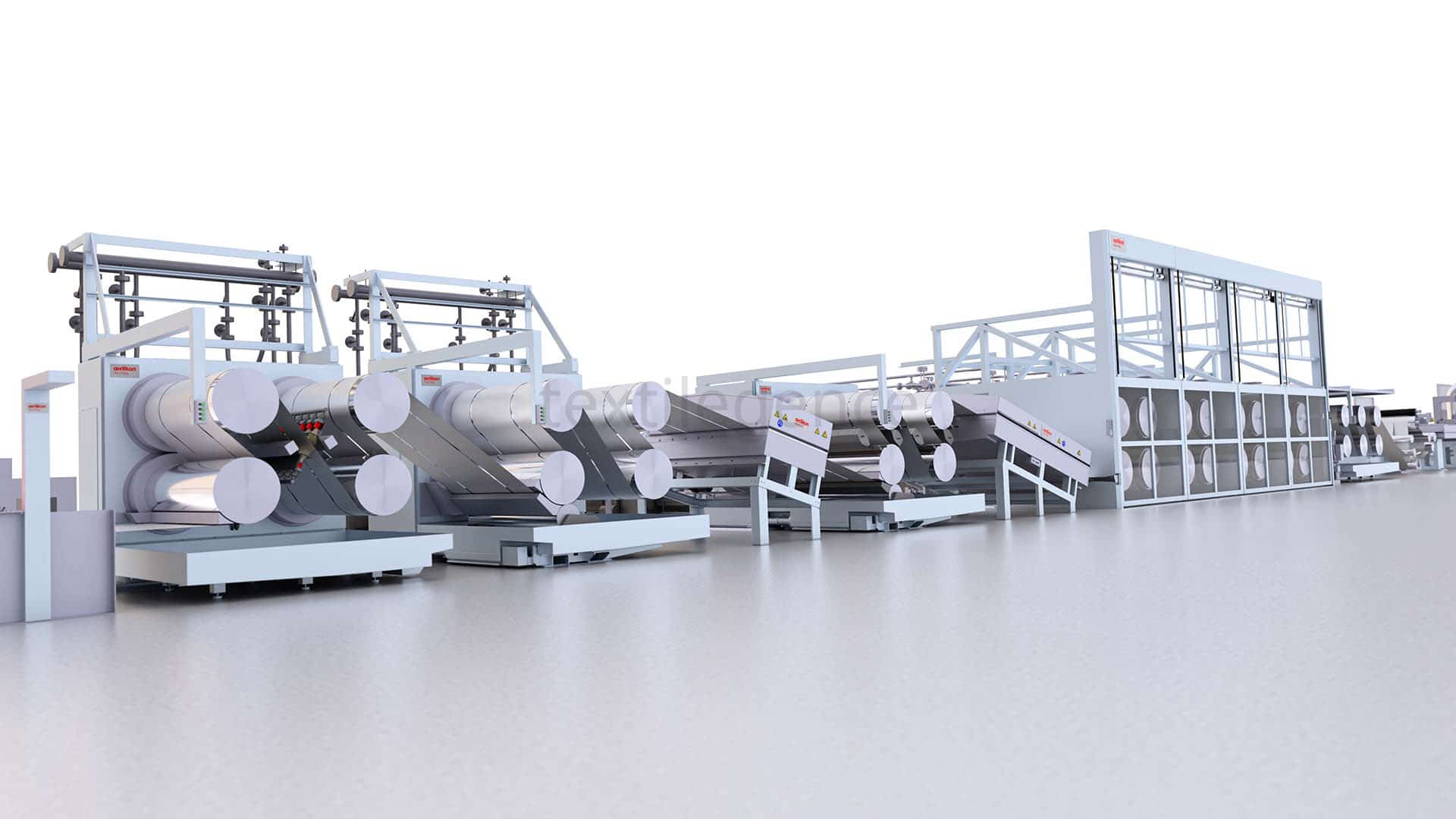

EvoSteam; sustainable production of staple fibers

The EvoSteam process from Oerlikon Neumag is considered a pioneer for more sustainable staple fiber production in the future. This offer impresses with savings in energy, water and raw material consumption, as well as a reduction in operating costs (OPEX) and the CO2 footprint – while at the same time achieving the excellent fiber qualities required by downstream processes and high production volumes.

New bicomponent BCF yarn for the carpet market

With its latest development in bicomponent yarns for carpet production, Oerlikon Neumag is meeting the carpet market’s demand for new innovative BCF yarns in terms of quality, efficiency and performance. Sales Director Arnd Luppold said that the new BICO BCF yarn is characterised by a richer and higher volume while at the same time significantly reducing the consumption of raw materials in carpet production.

At the company’s booth, interested parties can see sample yarns and carpets, find out about the product range and have in-depth discussions with the experts from Oerlikon Neumag about the advantages of BICO BCF yarn in various applications.

Into the future with atmos.io

Oerlikon has successfully maintained its activities in digitalisation with its Plant Operation Center (POC) for decades. Over 350 installations in large manmade fiber spinning mills around the world enable the control of complex systems with hundreds, even thousands of mostly WINGS POY or FDY winders. Besides, with atmos.io, it will be possible to process even more data in the future. This will give customers even more benefits and put them in control of the data flow in their business.