Saurer’s Autocoro 11 is redefining rotor spinning with its revolutionary technology for spinning even the shortest recycled fibres. With increased global focus on circular manufacturing and stricter environmental regulations, the demand for recycling in textile production is increasing. Saurer anticipated this trend and has developed multiple features displayed in the Autocoro 11 Recycling Xtreme version, making it the leading technology for circular spinning mills.

In its Recycling Xtreme (rX) edition, the Autocoro 11 fully automated rotor spinning machine processes even the shortest mechanically recycled fibres with exceptional raw material efficiency, unlocking new levels of circularity in yarn production. It also sets new benchmarks in energy efficiency, productivity and operational autonomy. Since its launch in 2023, mills worldwide have recognised its transformative potential.

Recycled fibres are obtained from pre-or post-consumer waste. Pre-consumer waste, often cut-offs from garment production, consists of fibres that are very uniform in type and colour, but vary in length due to tearing during the opening process. In post-consumer waste, mostly obtained from worn-out garments, the spinnability of the fibres is less predictable and requires a high degree of flexibility and fine-tuning of the settings by the spinning mill.

Saurer’s engineers have developed the smart features that allow Autocoro 11 to process a high content of shortest fibres from both pre- and post-consumer waste material. Recycling the fibres in a more circular way saves natural resources for the future of our planet. It is also a cost-effective alternative to virgin fibres, enabling mills to reduce their costs.

Highest flexibility and quality with Autocoro 11

The Autocoro 11 is a fully automated rotor-spinning machine. Precise adjustments for different fibres are easily done thanks to the single drive technology. By fine-tuning the yarn twist, speed of the opening rollers and rotor size, it is possible to achieve a recycled yarn quality which almost matches that of yarns made from virgin cotton. The wide range of adjustment options open new ways for spinning mills to achieve greater profitability and flexibility in yarn production.

Polat İplik Tekstil in Türkiye is one of the manufacturers, utilising Autocoro 11 for their sustainable high-speed spinning with lowest energy consumption. Fahri Polat, owner of Polat İplik Tekstil, is profiting from the benefits of Recycling Xtreme technologies: “For 40 years, we have been focussing on yarns made from recycled raw materials, where quality is paramount. With the Autocoro 11 and the Recycling Xtreme equipment, we now have a much higher raw material utilisation and can guarantee outstanding yarn quality. We now produce better and at the same time more economically – a benefit for us and the environment”.

Customers worldwide appreciate also the quick start-up of the machines. “Thanks to Synchropiecing, we can innovate with smarter mixing strategies and increase the share of sustainable fibres – a benefit for our resources and profitability” he says and added that from the moment the machine starts, the advantages are clear – within minutes, all 816 spinning positions are running at full speed.

Quality paired with machine efficiency in recycling

Recycled cotton yarns have a narrower count range than those made of virgin cotton. While not all blends can be spun into both coarse and fine yarns alike with the necessary properties for further processing steps, the use of carrier fibres is essential to achieve sufficient yarn strength.

The finer the yarns are, the more carrier fibres with a homogeneous length, i.e. polyester fibres, are needed to have the required minimum number of 110 well-bonded fibres in the yarn cross-section and thus ensure adequate yarn strength and sufficient spinning stability. Increasing recycled content without adapting spinning settings, often leads to an increase in yarn breaks. Fortunately, the Autocoro 11 can compensate such increase of yarns breaks with the Synchropiecing 60 technology, always keeping the highest level of economic efficiency.

Higher productivity and less maintenance with Recycling Xtreme

The new yarn guides with their self-cleaning mechanism in combination with continuous blow-off increase productivity while significantly reducing maintenance costs. In a Turkish spinning mill, the manual cleaning intervals were extended from 3 days to 6 weeks – an impressive fourteen-fold increase! At the same time, productivity when spinning Ne 10 weaving yarn was significantly increased. Thanks to the new yarn guides, disruptions to yarn guide movements caused by deposits are now a thing of the past. The days of packages with uneven flanks are also a thing of the past – real progress that raises efficiency and quality in the spinning mill to a new level.

Interval cleaning for first-class yarn quality

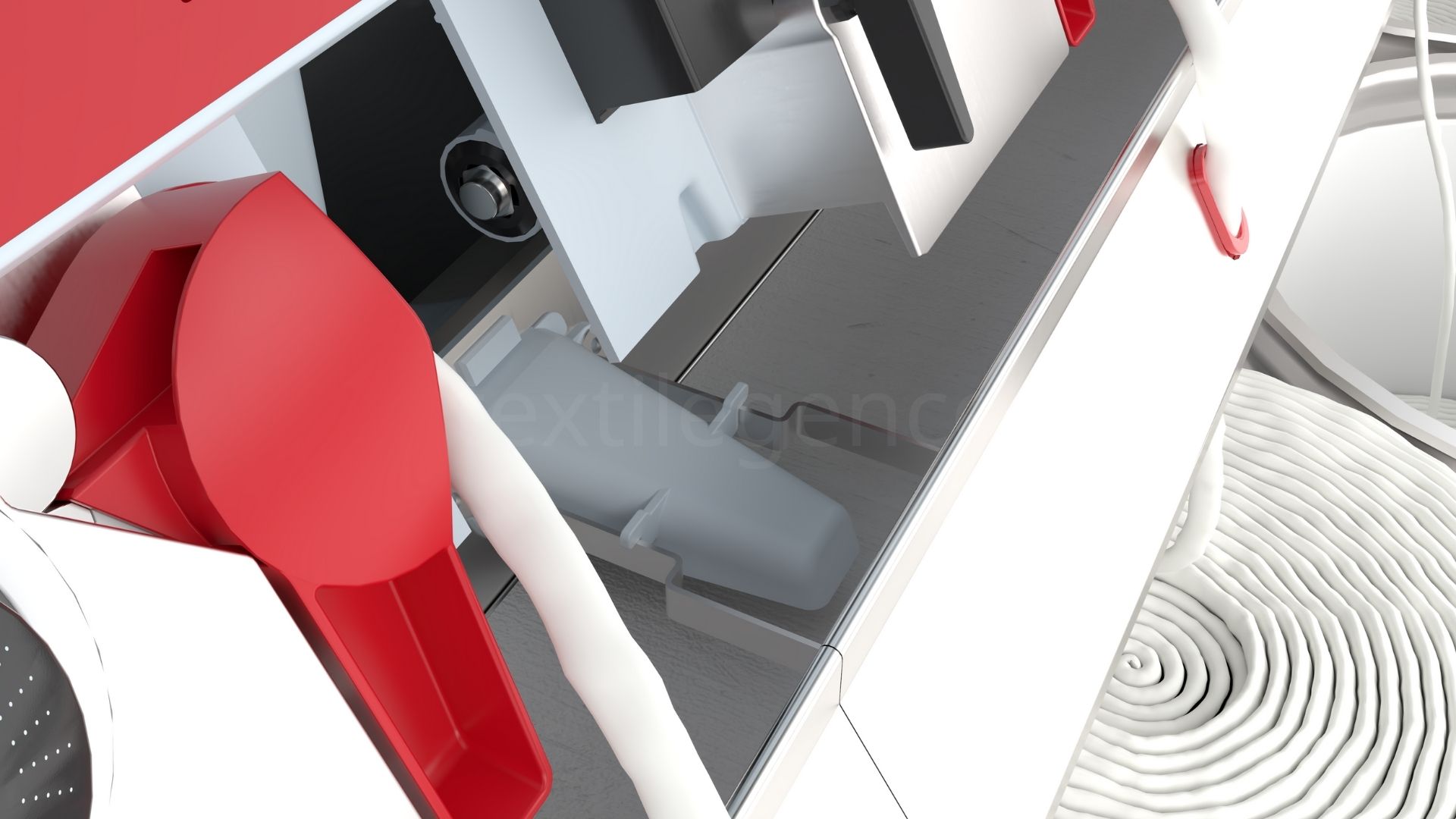

Recycled fibres tend to accumulate in the rotor grooves. Such contamination can impair the yarn quality and increase yarn breaks. The Autocoro 11 has an innovative solution to this problem: the new patented interval cleaning of the rotors implemented in the Doffing Cleaning Unit (Fig. 4).

State-of-the-art linear motor technology ensures that the cleaning process is now digitally controlled and perfectly synchronised. The combination of pneumatic and mechanical cleaning at regular intervals ensures effective removal of deposits. The recently integrated movement mode of the cleaning scraper optimises cleaning even further. A precise positioning of the scraper in the rotor groove ensures that deposits cannot stick in the first place.

All these advanced technology features enable excellent spinning stability and high, constant yarn quality. Yarn breaks are significantly reduced, and the processing of recycled fibres is made much easier on Autocoro 11 with Recycling Xtreme.