Türkiye-based ISKO, one of the pioneer brands in global denim market prefered Itema as the best fit for its strategy in weaving technology. They took an important step in terms of an even more sustainable denim future, by choosing Itema’s latest rapier machine, enhanced by the iSAVER® technology. The rapier machine ensures the highest efficiency by reducing waste production and energy use, while optimizing the fabrics’ hand-feel, aesthetic, and performance.

The decision of ISKO, the brand of SANKO Tekstil, represents another important step in moving towards Responsible Innovation™ which guides their work in redefining industry standards and their sustainability goals. Among the previous investments to reduce their environmental impact are R-TWO™50+, a new denim generation made with a minimum of 50% pre- and post-consumer recycled blend, and the Green Machine, a pioneering technology providing a 100% post-consumer recycling solution that fully separates and recycles cotton and polyester blends at scale.

This collaboration creates a common ground of excellence

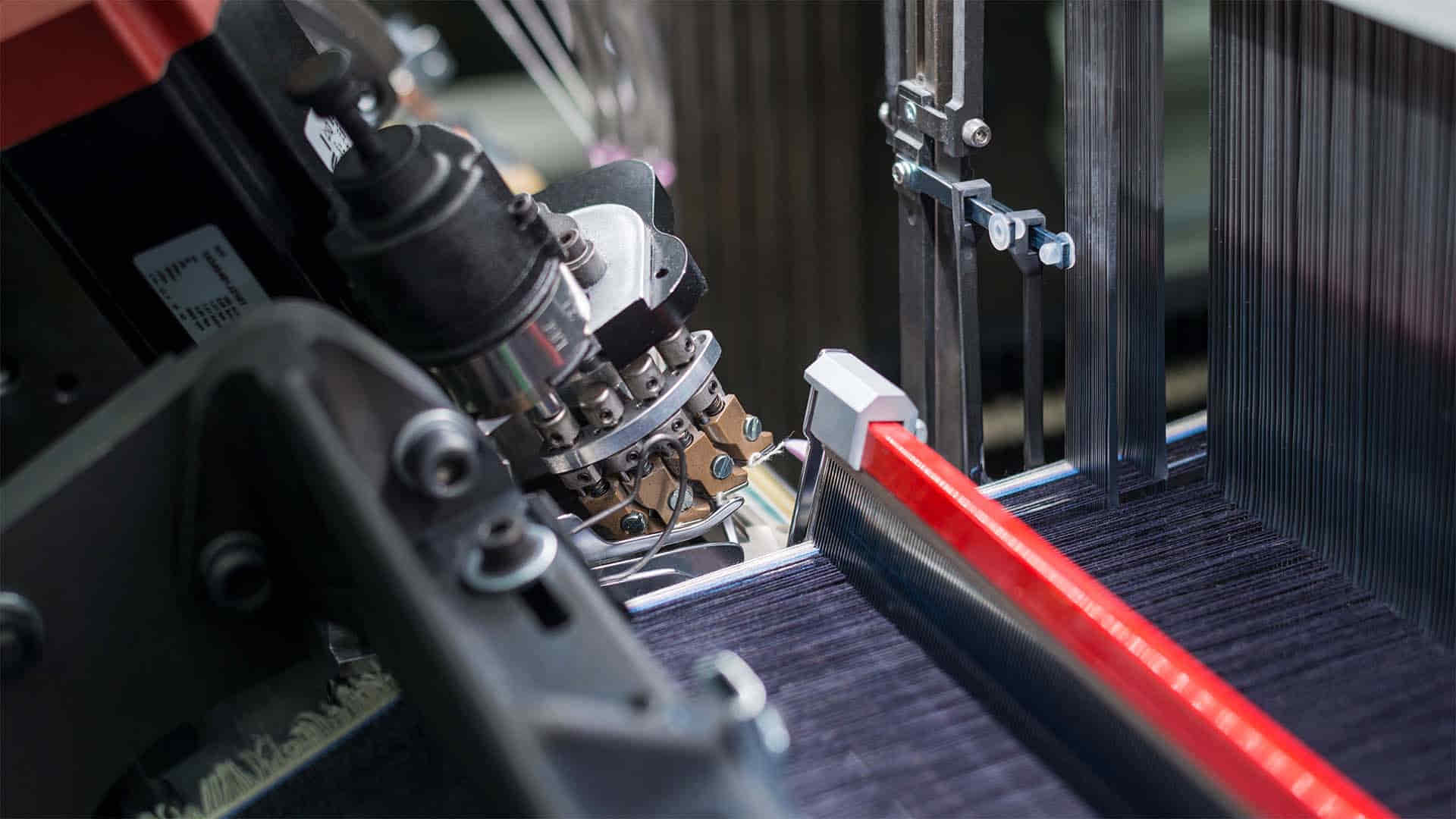

After an intensive process, a selection was made where ISKO focuses on the development of technical solutions that enable greater resource savings and more sustainable production methods, as well as the protection of workers. As a result, ISKO’s Headquarters extend the company’s long-term relationship with Itema, strengthening the company’s position as one of the mills with the world’s largest denim capacity. The new rapier machines are enhanced by the iSAVER® technology, a breakthrough mechatronic innovation that eliminates the waste selvedge on the left side of the fabric, allowing for saving in energy and raw materials, cutting in half the cotton waste that typically results from the weft yarn. All types of ISKO’s innovative fabrics, with a multitude of different constructions and fiber mixtures, can now be produced using these advanced weaving technologies, with a special focus given to the R-TWO™ technology in terms of its sustainable credentials.

ISKO CEO Fatih Konukoğlu said that in these innovations, they saw a great potential to advance their sustainable strategy even more, and in Itema the ideal partner with which to share a determined, long-term approach. He added: “Both our companies are leaders in their respective fields, fabric innovation and weaving technology, and this collaboration creates a common ground of excellence that will certainly benefit the whole denim world.”