KARL MAYER at Techtextil INDIA with technical solutions. KARL MAYER will participle with its Business Units Warp Knitting, Warp Preparation and Technical Textiles in the seventh Techtextil INDIA trade in the Bombay Exhibition Centre from 20 to 22 November 2019. Developing warp knitting solutions for technical textiles including composites, the company will be there with a 20 m² stand in the German Pavilion.

At this year’s trade fair, there will now also be an area for composite materials with the World of Composites. KARL MAYER Technical Textiles hopes that this expansion will have a positive effect on the visitor response. “Composites are an important area in India. Until now, there has been no specific trade fair for this sector,” says Hagen Lotzmann, the Sales Manager for the KARL MAYER Technische Textilien GmbH.

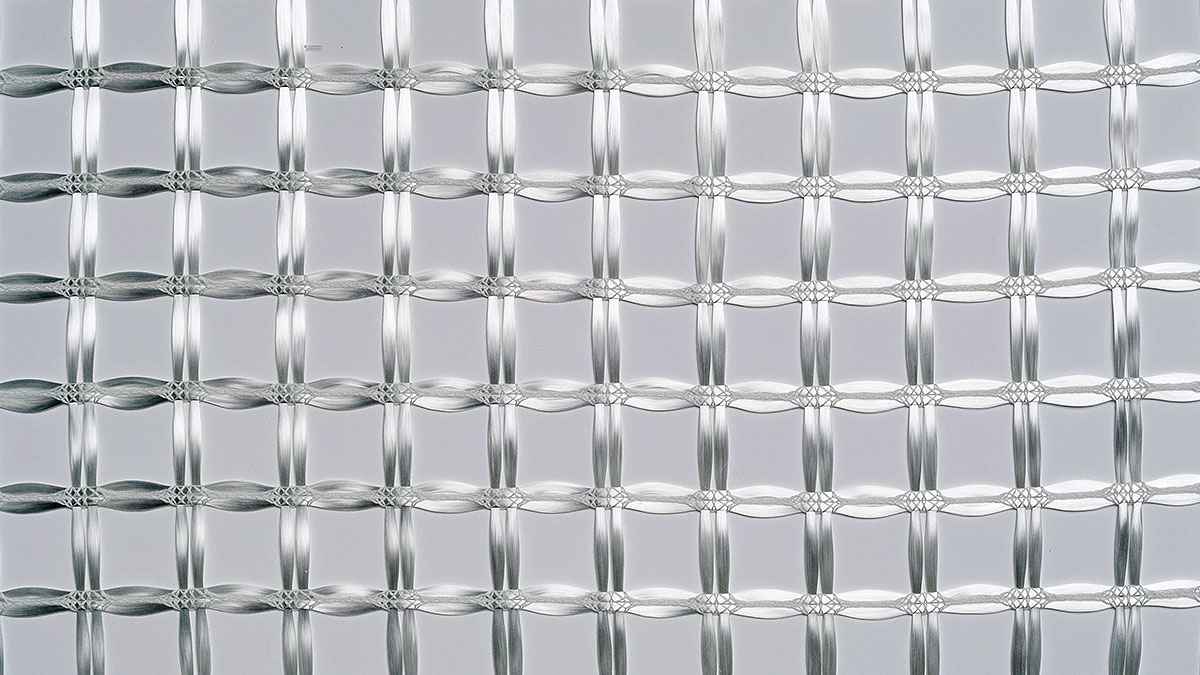

The subsidiary of KARL MAYER produces innovative warp knitting machines with magazine weft insertion, as well as high-performance bi- and multiaxial warp knitting machines, and will be demonstrating at Techtextil INDIA how the textiles produced on them can be used in innovative applications in the future. “We will be exhibiting at Techtextil in India as a supplier of complete solutions,” says Hagen Lotzmann.

KARL MAYER at Techtextil INDIA with technical solutions

There is a particularly high demand for warp-knitted geotextiles in India. These stable textiles are being used, for example, for reinforcing slopes in road building projects, for stabilising waterway banks in coastal engineering projects, and for covering landfill sites. Other lucrative applications include printed advertising media and lorry tarpaulins. This Sales Manager is expecting to receive many enquires from the wind turbine sector. “Multiaxial textiles produced from glass on multiaxial warp knitting machines are mainly being used to produce the rotor blades. A number of promising projects are already running on this particular application in India,” explains Hagen Lotzmann.

Further topics at the KARL MAYER stand are high performance warp preparation equipment; for processing technical yarns and the subject TERRY.ECO with KARL MAYER’s offers for a sustainable and efficient production of terry fabrics.

The emphasis will be warp knitting production instead of weaving; with which costs can be reduced by 30% and at the same time it is the more sustainable method for our planet. Karl Mayer offers complete machines for the production of terry fabrics; warp knitting machines with online brushing, warping machines for filament yarns and warping machines for staple fiber yarns. The TM 4-TS EL warp towel knitting works at an impressive efficiency level. Working at a width of 186″ and a speed of 800 rpm; the TM 4-TS EL has a daily production rate of about 1,800 kg of terry fabrics; at a weight of 400 g/m2. This means 250% more production than on an air-jet loom.