Circular knitting machine specialist Mayer & Cie. will present its innovations for the Turkish market at the ITM in Istanbul on June 4-8. Among the company’s solutions at booth 303 B in Hall 3. are two machine types – the SF4 3.2 III and the Relanit 3.2 HS II – and various smart solutions that make circular knitting more efficient. knithawk, a tool for the optical detection of knitting defects, ensures that yarn and energy are used in a valuable way. As efficiency also comes from durability, Mayer & Cie. strives to preserve its machines and their functions: Upgrade kits offer rejuvenation cures for existing machines and conversion sets create additional areas of application.

Managing Partner of Mayer & Cie. Benjamin Mayer disclosed that they are convinced that the ITM show will drive the textile machinery sector forward by providing a platform for industry leaders to network, share ideas and showcase progress, saying this can stimulate innovation, kick-start investment and ultimately drive the sector forward after a period of stagnation.

Make the tried and tested even better with Mayer & Cie.’s Relanit 3.2 HS II

Relanit 3.2 HS, which is by far Mayer & Cie’s best-selling machine, will also be the center of attention at the ITM. Customers appreciate its productivity, especially in connection with elastomeric plating. The mechanical single jersey model processes a wide range of yarns and qualities extremely reliably. The machine also impresses with its energy efficiency: Relanit 3.2 HS offers the advantage of 30% lower energy consumption compared to circular knitting machines with traditional technology.

In its updated form, the Relanit 3.2 HS II is equipped with a new thread guide, which makes threading of the elastic thread much easier. Models already on the market can be upgraded to be equipped with the new yarn guide.

Another innovation the Relanit 3.2 HS II is equipped with are improved needles and sinkers: The needle with serrated edge and predetermined breaking point, developed jointly with Groz-Beckert, prevents it from breaking uncontrollably under high load or a defective needle tongue and, in the worst case, from breaking needle butts – which in turn requires more complex intervention by the knitter. Mayer & Cie. Senior Product Manager Axel Brünner said that with this improvement, they are reducing downtime for the Relanit 3.2 HS II. The new sinker was also developed jointly with Groz-Beckert.

SF4-3.2 III for lightweight 3-thread fleece fabrics

With its SF4-3.2 III, Mayer & Cie. is addressing a trend in the clothing industry that has been underlined by Turkish customers in particular: Lightweight elastic three-thread fleece fabrics in both pure cotton and cotton blends are very much in demand. Axel Brünner explained that in this new machine, they combine their tried and trusted S4 3.2 II and components from their MBF 3.2 such as the stitch formation.

New Control 5.0 machine control system

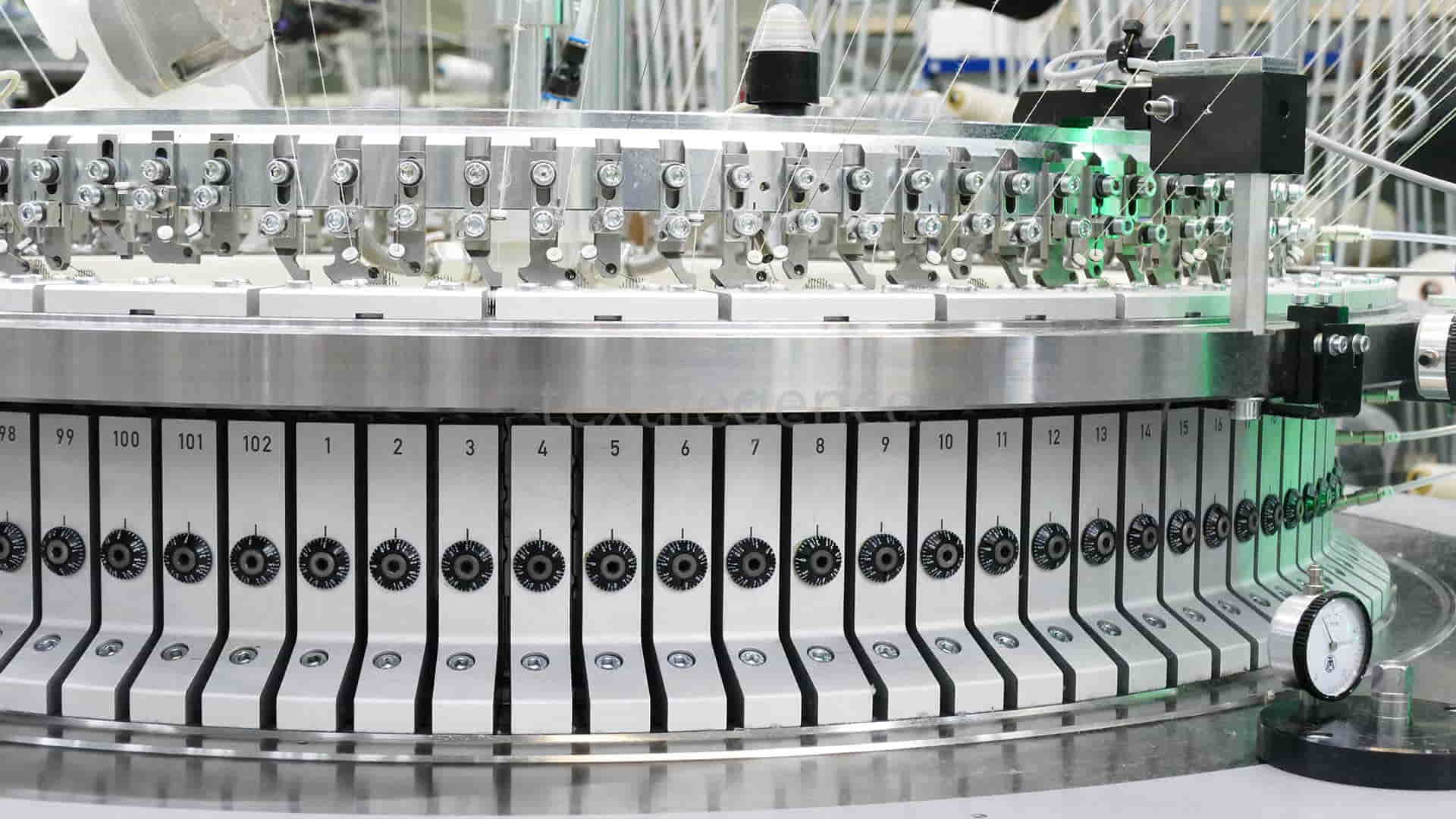

Both machines are equipped with the new Control 5.0 machine control system. It is available in two versions. In the standard version, it comes as SmartControl, which means that a so-called Smart Knob is attached to each machine foot. From there, all the functions that the machine operator needs for his work are available. All machines built from 2001 onwards can be converted, and selected new machines will be equipped with the new generation of machine control systems from 2024.

The ITM 2024 visitors will be able to discover knithawk for knitting defects, machine-specific upgrade kits and more at the Mayer & Cie. booth during the exhibition.