Saurer, a technology company with a focus on machines and components for yarn production, will welcome its visitors with its solutions for future trends at ITMA 2023 Milan. The company, supporting the textile industry in the areas of sustainability, digitisation, and automation, will exhibit the new Autocard SC7, the new and fully automatic Autocoro 11 rotor-spinning machine and many more at booth B101 in hall 2. The visitors will also have the opportunity to see Saurer machinery performances in first-hand with live demonstrations during the exhibition.

Saurer supports its customers towards a circular economy

Saurer offers many new features to optimise the processing of recycled fibres. Starting with the new Autocard SC7, for example: all drafting systems are driven independently and can be adjusted easily online to facilitate processing of recycled fibres. Increasing the carding area to over 4m2 makes it possible to gently process all fibre types and results in increased productivity. In addition to discover the more about Autocards SC7, the visitors can also see the BD 8 semi-automatic rotor-spinning machine live at the Saurer booth. The new Twinsuction system at both ends of the BD 8 results in energy savings and higher quality consistency. Automatic package removal makes it possible to change a package by simply pushing a button. This ergonomic solution allows operators to change packages easily.

Another important solution at the booth, the new, fully automatic Autocoro 11 rotor-spinning machine is the 4th generation of Autocoro with individual drive technology, which is already operating reliably with more than 1 million positions worldwide. Equipped with the Recycling Xtreme rX edition, the new Autocoro generation is tailor-made for recycled fibres. In addition, the Autocoro 11 shines with more powerful automation and with a new LED-supported operator guidance system, which further enhances the high productivity of the Autocoro 11.

The Saurer booth will also include the Autoairo, which sets new benchmarks for producing high-quality air spun yarns, named Belairo and the energy-efficient Autospeed roving frame with automatic doffer, which allows spinning mills to be less dependent on the availability of skilled personnel and at the same time increases the quality of the roving. At the ITMA exhibition, the Autospeed will be combined with the bobbin transport system, with Roweclean, the automatic tube cleaner and the Rowestore empty tube magazine.

Sustainable and economical solutions for the short and long staple sector

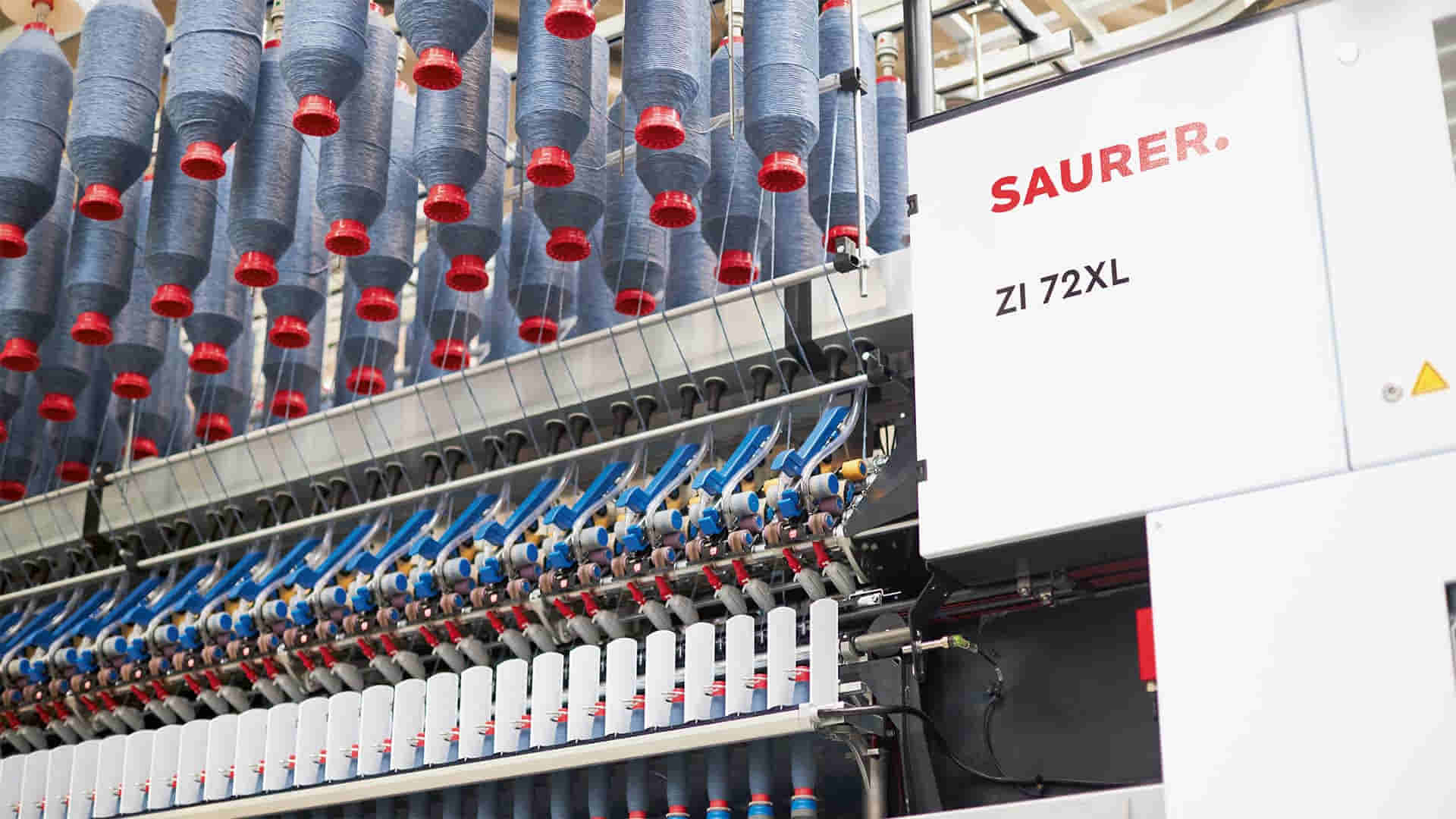

Saurer, one of the pioneers for sustainable and economical solutions in ring-spinning, will present machines for the short and long staple sector at ITMA 2023. The highly productive ZI 72XL compact-spinning machine offers a high degree of flexibility for almost all applications and is suitable for recycling fibres. Featuring the new self-cleaning compact yarn system Impact FX pro with multihole aprons, the ZI 72XL delivers excellent yarn values for standard and recycled yarns, especially for fine yarns. In addition, the ZI 451 worsted compact-spinning machine for woollen and acrylic yarns will be on show at the Saurer booth and will delight worsted spinners with its high flexibility and profitability.

The Texparts product line supplies high-quality components for ring and rotor-spinning that ensure excellent yarn quality and maximum productivity. The newly designed PK 1580 drafting system for roving frames is designed ergonomically and easy to handle. Fast and precise adjustment of the load with narrow load tolerances is important for processing a wide range of fibres and is also advantageous for recycled fibres.

In addition to the CompactTwister, which can twist recycled yarns and thus increase the strength for the downstream process, Saurer will also present its offers to reduce energy consumption including the new Texparts spindle Eshape, CarpetCabler/CarpetTwister 1.12 and CakeFormingWinder. The automation solutions for spinning and twisting will be also at ITMA.

Saurer’s customer support experts in the booth await to inform visitors about solutions available to increase the quality, performance, and profitability of the production plants.