Sperotto Rimar, a member of Santex Rimar Group and one of the leading manufacturers of textile finishing machines, will present its product portfolio which offers both ingenuity and sustainability at ITME India 2022 to be held at IEML in Greater Noida, Uttar Pradesh on December 8-13. Visitors to the company’s Stand H5F5 in Hall 5 will have the opportunity to get first-hand information about solutions that meet customer needs for smart innovation and eco-friendly production, bringing an ideal look, touch and functionality to various different applications.

Sperotto Rimar follows two energy-saving strategies in machine development for fabric finishing. The first aims at technology which skips one or more production steps to shorten the finishing process. Equally important is the use of innovative components such as motors, electrical and electronic controls, which can significantly reduce energy consumption.

Optimizing finishing processes is another way to save energy. For the highest potential for energy saving today, it is important reducing the use of steam, water or electricity in processing, and adopting technical solutions to limit, or partially recover, the energy consumed.

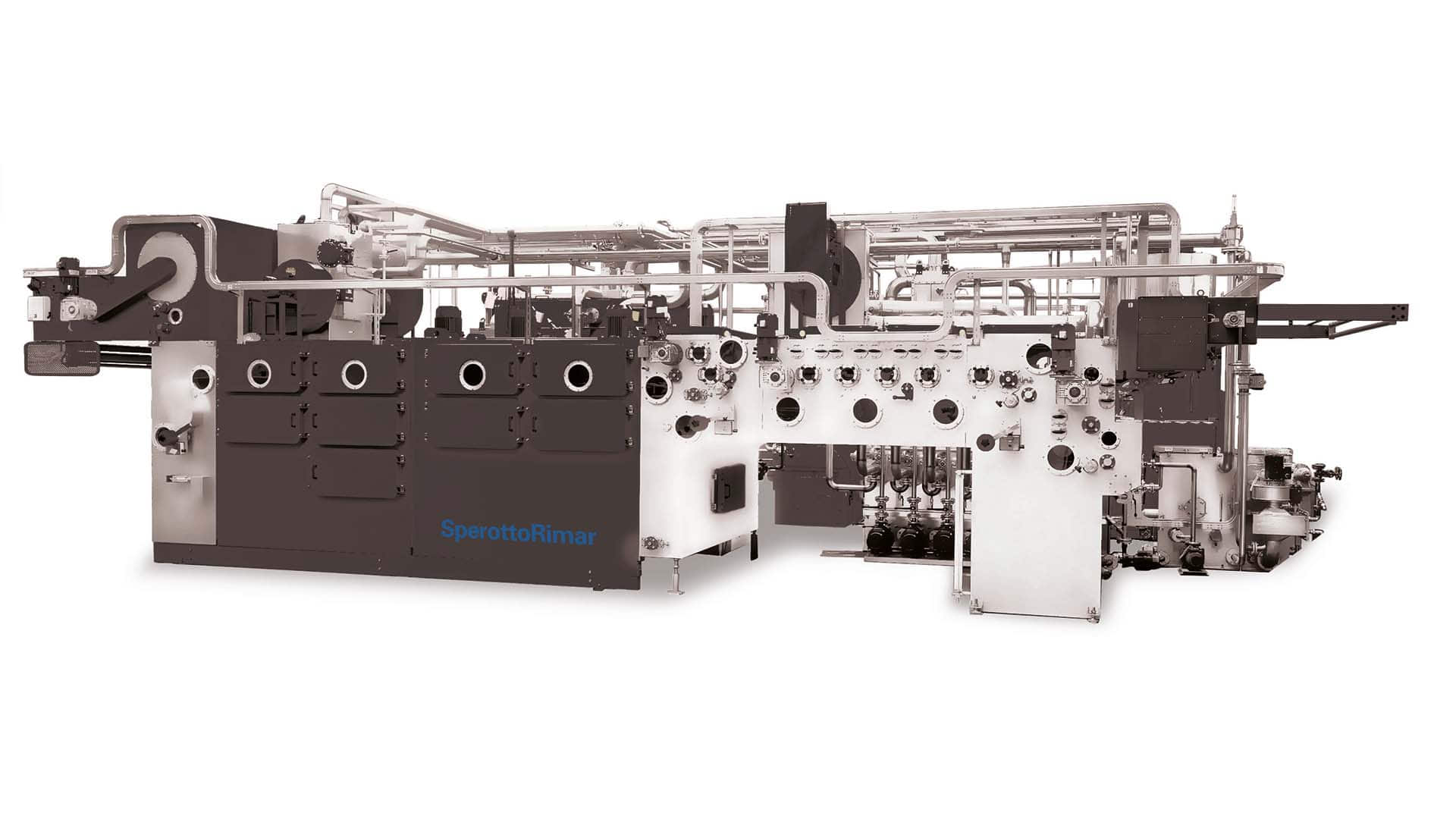

Sperotto Rimar offers a big impact in finishing with a shorter process

The Decofast decatising machine offers significant energy savings with the substitution of a discontinuous process. On certain fabric types, it allows users to skip one pass of direct steaming with pressure. This shortened process results in lower energy consumption and requires less labour. The technology enabling more sustainable decatising was actually introduced at the beginning of 2000, long before finishing customers demanded machinery with reduced environmental footprints or urgent solutions for energy-saving needs.

The Universa fabric relaxing machine provides %30 less steam and energy

The Universa fabric relaxing machine can be used wherever relaxing, shrinking and bulking effects are required. It has wide application in different finishing fields – from wool to synthetic fabrics. Universa was designed to drastically reduce steam consumption. Tests prove that 30% less steam is needed compared to traditional technology. Conclusively, the machine needs 30% less energy while achieving the expected quality results.

Novaone recycles more than 99% of the chemicals used in the process

Novaone, one of the most eco-friendly solvent scouring machine for the past 50 years, includes in the market as an ideal alternative to traditional water scouring for the washing of synthetic fabrics. The technology has been continuously improved and therefore it facilitates excellent cleaning performance on various materials. The machine recycles more than 99% of the chemicals used in the process.

Compas reduces the compacting belt temperature

Sperotto Rimar’s Compas open-width compacting and finishing machine for knitted and woven fabrics uses an indirect water-cooling system to reduce the compacting belt temperature. With this system, the water is recovered by passing it through a chiller to keep its temperature at the right level. This technology can save about three cubic meters per hour. This water, totally unpolluted, can be continuously recovered and re-used in the machine.

Another feature enables a minimal environmental footprint through technology-based process optimization. Chemicals used before the dry finishing process are typically softeners or resins to enhance the final appearance and touch of the fabric. These are then transferred to the final garment. It is possible to reduce significantly the level of such chemicals, since the machine partially compensates for the effect of these chemicals. Thanks to its unique compacting method, Compas imparts a silky touch, only partly attributable to the softeners used, while mainly deriving from the special materials in the machine design.

Natural stretch is usually obtained by inserting elastane (a synthetic elastic yarn) during the weaving phase. The elastane itself, however, is difficult to deteriorate. Compas ensures the same degree of elasticity but with a final product that is 100% ‘natural’. Thanks to technology, saving the environment no longer means end-users have to compromise on the touch and feel of fabrics.

Sperotto Rimar also always chooses machine components from latest-generation technology, aiming to save as much energy as possible. For example, the motors installed are of the IE 3 type.