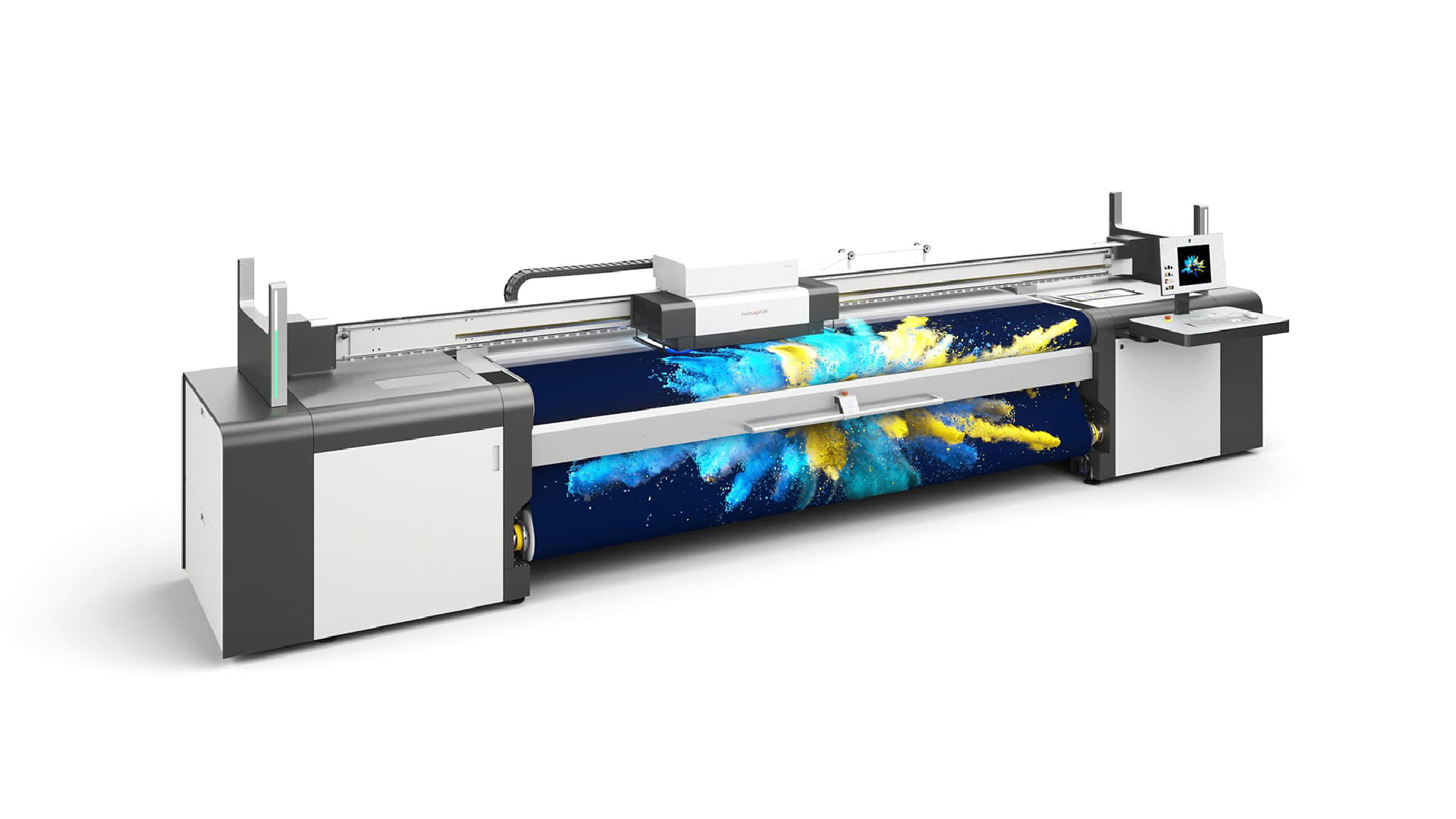

Swiss UV inkjet printing systems specialist swissQprint presented the second generation of its Karibu UV roll to roll printer at the Printing United Show in Las Vegas. The company, represented by Pigment Reklam in Türkiye, is taking UV roll to roll printing quality to a new level by means of the latest print head technology. Karibu 2 achieves up to 1350 dpi resolution, delivering top quality even at high output. It accommodates rolls up to 3.4 metres wide and prints using UV inks that are flexible, NVC (N-Vinyl-Caprolactam) free and Greenguard Gold certified. Unique features of the new genaration printer ensure high efficiency and reliability as well as outstanding versatility. SwissQprint Chief of Sales and Marketing Officer Carmen Eicher said that they took these proven and popular features from the first generation and have now augmented them with the latest print head technology.

swissQprint Karibu 2 doubles productivity

Thanks to the cassette system, rolls are loaded and ready to print within minutes. swissQprint offers a dual roll option capable of handling two rolls each up to 1.6 metres wide and this doubles productivity. The roll holders are split into two sections with each half of the shaft driven individually to ensure optimum web tension and perfect results on both rolls.

The Karibu vacuum plate is divided into 136 individually operable segments. The vacuum can be selectively adjusted within four seconds, whatever the roll width. Hence there can be no air leakage, even though the space between dual rolls.

Convenient backlit and mesh printing

Karibu features a Light Box right next to the printing area, for immediate and continuous quality control of backlit prints. As a result, neither much material nor time is lost should optimisations prove necessary. A Mesh Kit is also integrated right next to the Light Box. This makes clean and simple work of processing permeable substrates, as well as full bleed printing. There is neither additional set-up work beforehand nor cleaning afterwards. A mouse click by the operator sends the beam from its standard position to the mesh position. Printing can then start immediately.

Automatic double-sided printing

For media that needs to be printed front and back, swissQprint offers an automatic double-sided printing function. Karibu controls the process with the help of an integrated high-resolution camera system and QR codes printed next to the image. This ensures that subjects printed on the reverse side are positioned with perfect registration, matching the correct image on the front. Lory, the intuitive output software, guides operators through the process, thus enabling them to to do less work, and minimizing the risk of errors.