Itema, the leading Italian manufacturer of best-in-class weaving machines, spare parts and integrated services; is exhibiting at DTG Dhaka (Hall 7 / 510) from January 9th – 12th at BICC – Bangabandhu International Conference Centre in a joint booth with its sole agent in the country Pacific Associates.

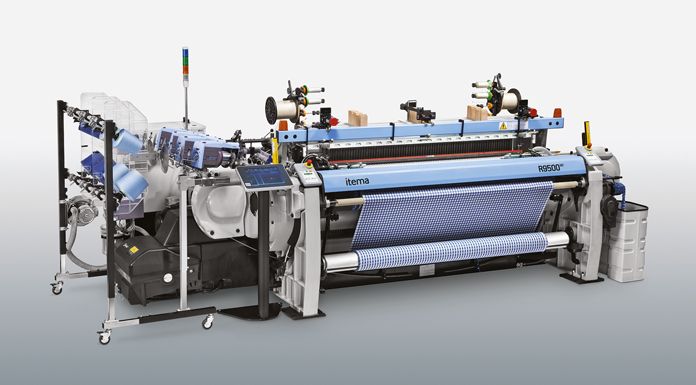

The Italia based Company will showcase its absolute worldwide best-seller; the Itema rapier machine R9500. The R9500 on show, courtesy of the Itema Customer Well Group based in Chittagong; will exhibit a shirting fabric which represents one of the most produced in the Bangladeshi weaving mills. The Itema target is to demonstrate to the industry the textile superiority; the real production performances and the excellent efficiency of the R9500 when it comes to weaving the widest range of fabrics, including shirting, apparel, bed sheeting.

DTG is for Itema the perfect stage to allow the Bangladeshi weavers to experience first-hand the advanced weaving technology and the worldwide Itema references; in what is defined as one of the future leading countries in the woven fabric production.

Bangladesh stands out in textiles

In fact, despite garmenting is a major industry in Bangladesh the biggest amount of fabric required is still imported from other countries. In this landscape, the future development of the weaving industry represents one of the main potential sectors for growth of the Bangladeshi textile industry.

Itema positions itself as a reliable partner – and not only a simple supplier – for textile companies; providing best-in-class, made in Italy weaving machines along with a real-time after-sales service; highly professional trainings for the weavers and integrated textile consultancy.

Itema is uniquely positioned in the market to offer textile manufacturers the top three weft insertion technologies – rapier, airjet and projectile, OEM spare parts, upgrade kits; and a the dedicated online shop MyItema for the historic brands now part of Itema – Somet, Sulzer and Vamatex; plus highly professional trainings in 6 worldwide locations.

Itema, as a customer-oriented Company, wants to give to the Bangladeshi textile entrepreneurs a valuable option in the market; and features a solid organization in the country, relying on a trained and professional locally based team of technicians.

The Italian representatives of the Company along with the Bangladeshi Itema dedicated team will be at DTG to meet the industry players; to listen to their needs and to show to them the multiple possibilities and advantages that they could get by dealing with Itema.

R9500 Rapier Weaving Machine

Since market launch end of 2012; the Itema R9500 has become an absolute best-seller and one of the most highly reputed and successful rapier looms in the history of weaving. With the widest application range, the R9500 is the backbone of Itema. It is simple to operate and maintain producing unsurpassed quality and high added value. With virtually no limits to versatility, the R9500 enables the Customer to embrace new opportunities and quickly penetrate new markets

Technical features; top weaving performance; compact and solid structure with low vibration and requiring less space; TurboProp system with less moving parts; optimized open shed geometry, less yarn friction/stress, less stops; optimum fabric quality; versatility in weft cutter device; option of either motorized electronic or rotocut; reliable electronic NCP platform (New Common Platform – same as on A9500 airjet machine); low maintenance costs, longer oil interchange, less oil consumption; user-friendly touch-screen with graphic capability; remote loom control via LoomBrowser; iPOS Intelligent Productivity Optimizing System designed to maximize fabric productivity.

The re-designet sley and back rest modules represent key new developments. The new sley design promotes speed & versatility; while the new back rest modüle enables less warp tension and a cleaner shed.

The new developed FPA 2.0 – Free Positive Approach – weft transfer combinines the versatility of a positive rapier system with higher performance and efficiency; allowing customers to weave with endless creative possibitties even the most sophisticated fabrics