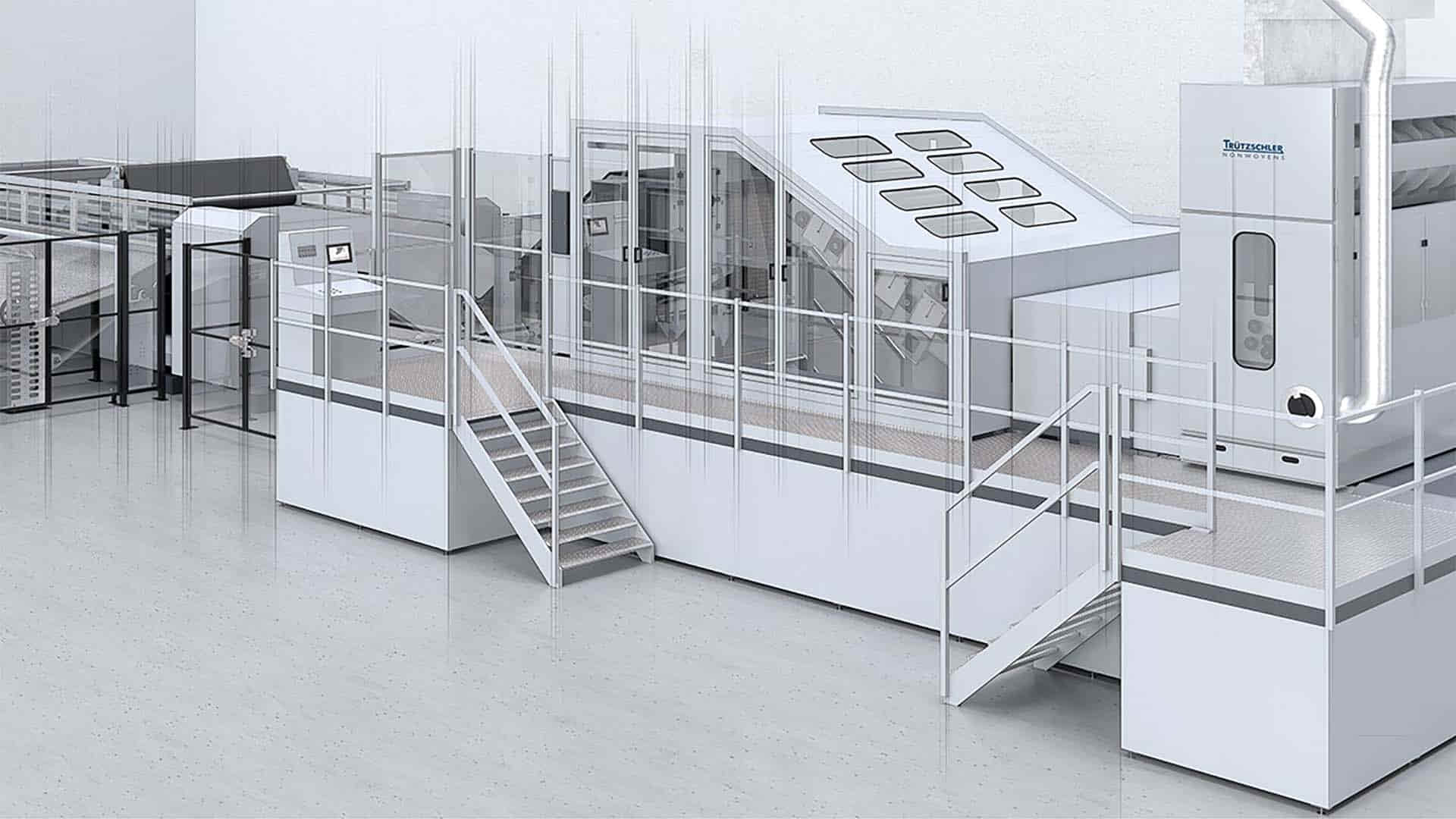

Trützschler Nonwovens & Man-Made Fibers GmbH started a cooperation with the Italian textile machinery manufacturer Texnology S.r.l. in the field of needle-punching technology. The companies will offer complete production lines for needle-punched nonwovens under the name of T-SUPREMA with immediate effect. Trützschler Nonwovens contributes its many years of experience in fibre preparation and web forming to the cooperation, while Texnology is mainly responsible for the needle-punching process. In this context, it was stated that a first joint project has already been successfully completed, implemented and put into operation.

Trützschler Nonwovens Managing Director Klaus Wolf stated; “With Texnology, we have an innovative and reliable partner at our side. The company already sets an important course in the field of needle-punching machines through excellent and patented solutions,” regarding the topic. Wolf disclosed that Trützschler Nonwovens is returning to needle-punching solutions and explained that in this partnership, they are able to serve this interesting market segment with precisely fitting production lines. Wolf added that needle-punching became as easy as never before with T-SUPREMA.

Owners of Texnology S.r.l. Nicola and Paolo Olivo stated that they saw the joint activities as an opportunity and said; “Texnology has developed its own needling technology with patents and profound know-how. Collaborating with a well-known, globalized company like Trützschler Nonwovens will significantly increase our target group.”

Carrington Textiles announces new head of sales for northern and eastern Europe

Carrington Textiles, a global workwear textile manufacturer, announced the appointment of a new member to their team, Jenni Brown, who has taken responsibility for sales in northern and eastern Europe, working with already established teams in these geographic markets. With a wealth of experience in textiles and global sales, Brown will help drive the company’s ambitious growth plan in Europe as the new head of sales. Brown previously held the role of UK & European Sales Manager for knitwear brand John Smedley, Head of Key Accounts for Simon Jersey and, latterly, Business Development Manager for Cintas UK.

“I look forward to working as part of the Carrington Textiles team”

Jenni Brown stated that she is delighted to join and be a part of such an innovative brand and made the following statement about her new role; “With over 20 years of experience within the fashion and corporatewear industry, I understand customers’ needs and requirements, this, therefore, feels like a natural career move. I look forward to bringing our new developments to market and working as part of the Carrington Textiles team to continue the growth of our market share”.

Carrington Textiles Sales Director Paul Farrell stated that they are pleased to welcome someone with such great experience and skills like Jenni Brown in their team and added; “She is the perfect fit for our continued growth in northern and eastern Europe and I am excited to see what the future holds not only for our company’s strategy, but also for Jenni’s career development”.

Sasa’s orders increased by 20% due to the outbreak

Turkey’s largest polyester producer SASA, has achieved a 20% increase in orders due to the outbreak of coronavirus. The Adana-based company produces 700 thousand tons of polyester annually and approximately 60% of this production is supplied to the technical textiles manufacturers of health, hygiene and packaging products.

In his statement to Anadolu Agency, SASA General Manager İrfan Başkır stated that 2019 is a starting year in which the planned investments gradually come into action. Stating that SASA within Erdemoğlu Holding has realized a serious investment move, Başkır reminded that the polyester production capacity increased from 350 thousand tons to 700 thousand tons annually with the commissioning of the polyester fibre facility. Reminding that a 250 million dollar fibre plant investment has been made, Başkır said; “Our capacity will reach 1.4 million tons this year; with the second phase investments in May and the third phase in June”.

Sasa’s orders increased by 20% due to the outbreak

Technical textiles news: textile waste comes back to life with Fibersort

The Netherlands-based Fibersort consortium presents the market ready Fibersort machine to the industry; a cutting edge automated sorting technology that revolutionizes textile to textile recycling of post-consumer textiles. Obtained as a result of a long project period, this technology opens new opportunities in the recycling of textile wastes.

The accelerating consumption and disposal practices in fashion cause textiles entering the market to reach their end-of-use rapidly. In North-West Europe alone, around 4,700 kilo tones of post-consumer textile waste is generated every year, a small portion of the global mountain of textile waste. On average, only 30% of these textiles are collected separately- the rest is lost within household waste. In the best-case scenario, these textiles are sold in the second-hand market both locally and internationally. The remaining textiles are considered non-rewearable textiles due to their unsuitability for the second-hand market or the market saturation that second-hand clothing is currently facing. Almost all of these textiles are currently being downcycled, incinerated or landfilled. Nevertheless, 24% of the textiles collected have the potential to be recycled into new textiles, but currently are not. These textiles represent 486 kilo tones per year, the equivalent to the weight of 50 Eiffel towers!

Textile waste comes back to life with Fibersort

Two specialists partner on new garment illumination

Coats, the world’s leading industrial thread company, is partnering with Osram, the global lighting specialist, to launch Coats Signal Active Illumination to help improve people’s safety and visibility.

Coats Signal Active Illumination is a state of the art washable, lightweight and customisable LED light system designed for application in garments and accessories. Visibility range is approximately three times more than retro-reflective products are able to achieve.

Coats Signal Active Illumination is made of flexible light guides which draw their energy from a USB power bank, the size of a credit card. It retains a charge for up to eight hours, which as the average length of a work shift, is especially relevant to those wearing it as part of their workwear. The power bank can be easily unclipped and removed to enable the garment including the LED light system to go through machine washing and drying processes.

Two specialists partner on new garment illumination

Technical textiles news: there is solution for every application at Oerlikon Nonwoven

Oerlikon Nonwoven will attend the nonwovens fair INDEX 2020, which will be held for the sixth time in Geneva, Switzerland, from March 31 to April 3, 2020. The company will display its solutions for nonwoven market and customer oriented hygiene, medical and other technical applications, and will focus on quality and optimum production process. Oerlikon Nonwoven, based in Neumünster, will demonstrate product and process expertise with the technologies it has developed.

Oerlikon Nonwoven meanwhile has a very broad range of spunbond technology products and services. The process for manufacturing geotextiles from polyester or polypropylene has been optimized; it is characterized by high production capacities and yields, with simultaneously low energy consumption for producing benchmark nonwoven products.

For the manufacture of hygiene nonwovens, Oerlikon Nonwoven offers its new QSR (Quality Sized Right) systems. Here, the benefits of the Chinese machine construction partner’s nonwoven formation are integrated into the complete solution. The advantage for nonwovens producers: highly competitive solutions at attractive prices with comparably low investment.

There is solution for every application at Oerlikon Nonwoven

Kordsa at the World of Concrete with its brand KraTos

Kordsa participated in the International Concrete Fair, World of Concrete (WOC) 2020, which took place in Las Vegas between 4-7 February. WOC hosted 60,000 visitors and approximately 1500 companies. Kordsa, the global player of the tire and construction reinforcement and composite technologies markets, attracted great interest with its competencies and the features of its innovative synthetic fibers Kordsa KraTos Macro and KraTos Micro used in concrete reinforcement applications.

Offering easy and fast application, KraTos Macro and KraTos Micro blend homogeneously in concrete and provide maximum performance. These two products, which differ in their longevity thanks to their high quality and corrosion-resistant structure; are sustainable, environmentally friendly solutions that release lower carbon emissions than steel reinforcements. Being the first Turkish product in the international synthetic fiber market, Kratos is highly preferred in infrastructure and superstructure projects. KraTos is used in a variety of construction applications; from industrial site concrete to screed, from high-performance under-rail concrete to port’s slab on ground concrete; from shotcrete to tunnel lining and precast concrete components.

Kordsa at the World of Concrete with its brand KraTos

Technical textiles news: protection increases while weight decreases with Aramid textiles

Protection increases while weight decreases with Aramid textiles. Aramid fibre yarns are now widely used in technical applications. They are used in composites, for example, in hard ballistic systems, lightweight transport containers; and laminated, high-performance sails, but they are also used in protective textiles – usually in woven textiles – for clothing. Compared to glass and carbon fibres that are also used, the specific characteristics of aramid yarns give them advantages; that can be used in a wide variety of applications – but these come at a price.

In particular, Aramid fibre have an exceptional impact resistance and energy absorption capacity. Unlike the versions made from carbon or glass, the aramid fibres are virtually undamaged by filament abrasion during processing. They can currently be processed on the COP MAX 5 multiaxial warp knitting machine; to produce non-crimp fabrics with a degree of uniformity that has never been achieved before. Fine, lightweight, channel-free reinforcing structures are produced for use in applications requiring a high level of force absorption; especially in new and lighter, soft ballistic systems.

Protection increases while weight decreases with Aramid textiles