The KARL MAYER Warp Preparation Business Unit has prepared a diverse media presentation of its extensive product portfolio for ITMA ASIA + CITME. The focus is on solutions that support its customers in successfully navigating the current tense global economic and geopolitical situation.

“We want to discuss ways of improving cost-effectiveness with our customers. Specifically, we want to talk about energy consumption, production costs, machine availability and the reproducibility of warp preparation results,“ says Dieter Gager, Vice President Sales of KARL MAYER’s Warp Preparation Business Unit.

CASCADE makes an efficient contribution to reducing sizing costs. The innovative steam and condensation system for the PROSIZE sizing machine uses up to 7% less steam in the drying process, thereby reducing energy costs, environmental impact and resource consumption. Practical experience, particularly in Pakistan and Austria, is generating growing interest in this innovative technology.

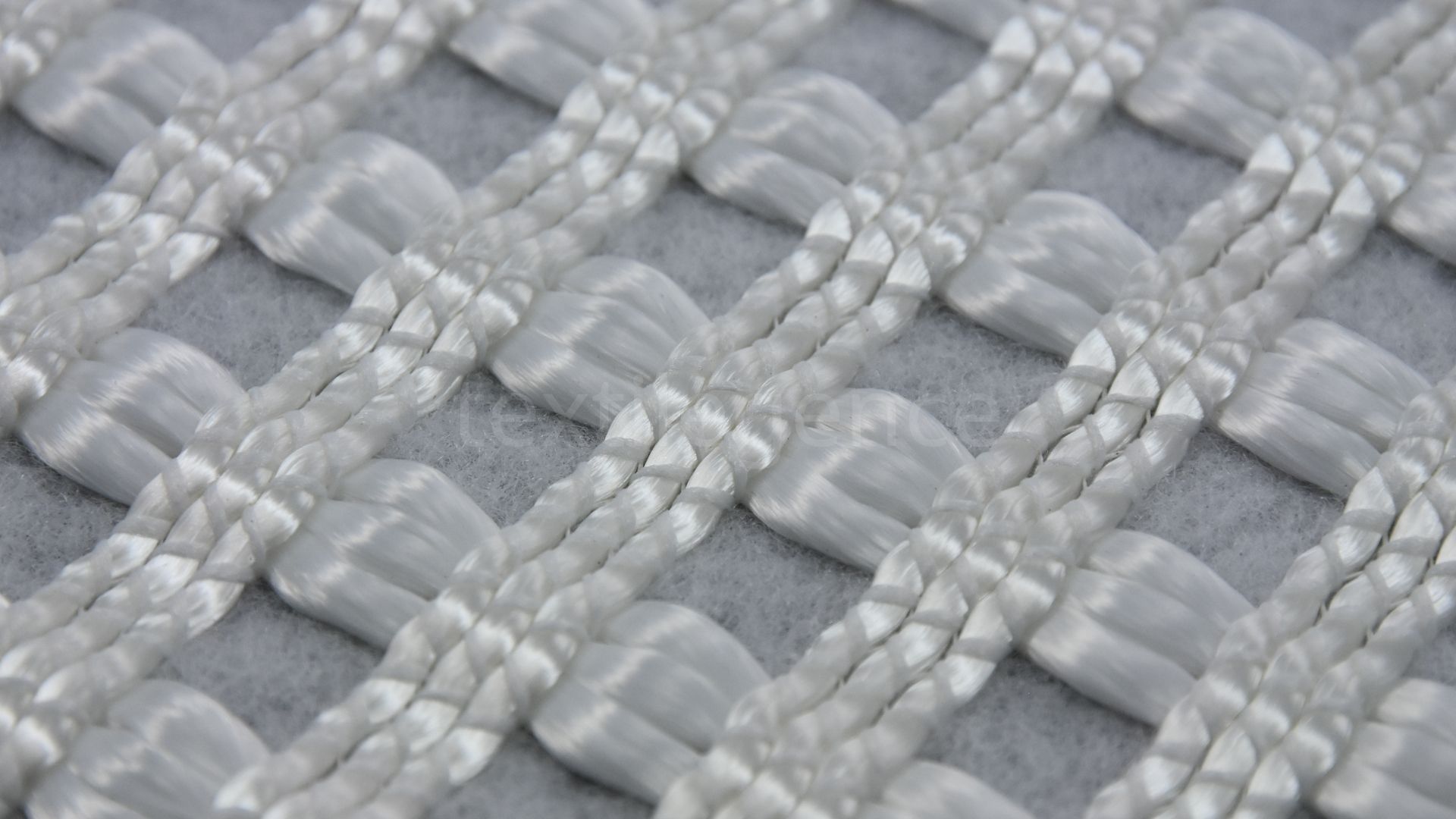

Continuing the story from last year’s ITMA in Shanghai, WARPDIRECT is also a highlight in Singapore. Practical experience with the new technology confirms the outstanding performance of this latest-generation beam warping machine. At speeds of up to 1,200 m/min, it offers unique output and produces warp beams of the highest quality. The top quality offers advantages in subsequent processes, including less yarn waste during the finishing process and maximum efficiency in weaving. In addition, WARPDIRECT scores with low maintenance requirements and maximum operational reliability – all at extremely competitive acquisition costs.

The machine operation improves with digital developments

Optimising the price-performance ratio of its machine offerings is an important development goal for KARL MAYER’s Warp Preparation Business Unit. In addition, the focus is on innovations for greater machine availability, particularly in the areas of predictive maintenance and condition monitoring. Digital solutions are intended to make maintenance stops programmable and minimise unwanted downtime.

Dieter Gager is looking forward to further discussions with trade fair visitors about new digital developments and how they can be used to expand the functionality of the machines.