Presenting its innovations on weaving segment, Staubli will take part in ITMA ASIA CITME with two different booths.

Stäubli will take part at ITMA ASIA 2016 in Shangai with its cutting-edge weaving and knitting technologies. The company will meet Asian market with both its booth in Hall 3 C28 and its DEIMO booth in Hall 4 D15. Owing an extensive range of textile machinery, the firm will present these solutions; shedding solutions for frame weaving (cam motions, dobbies), electronic Jacquard machines with harnesses, weaving preparation systems including automatic warp drawing-in and warp-tying machines, Schönherr carpet weaving machines. With its brand DEIMO, Stäubli will be exhibiting automation solutions for the knitting industry at a separate booth.

High-speed Jacquard machines for any application

Three complete Jacquard installations with different types of weft insertion will show their quali-ty weaving capacities at the two-level Stäubli booth featuring excellent vision on the whole machinery. Two set-ups showing the re-engineered Jacquard SX and LX machines will be weaving terry cloths and upholstery on rapier weaving machines.

The production of OPW airbags will be demonstrated by the Jacquard machine LXL for heavy payload with a weaving width of 280 cm. While the set up at the booth is equipped with a Stäubli harness with 12288 cords, this machine offers the possibility to achieve formats up to 36’864 by combining two ma¬chines in a tandem set-up.

In addition, Jacquard weavers can discover the redesigned version of the highly appreciated Jacquard machine DX, especially dedicated to the requirements of Chinese weaving ma-chines. As redesign at Stäubli goes with improvement of capabilities and characteristics, keeping always in mind the increase of the weaver’s ease and production performance, ITMA Asia is the occasion to achieve detailed information about the possibilities offered by this new version of the reliable Jacquard workhorse already performing in many Asian mills. The ma-chine will be showcased in combination with different types of Stäubli harnesses for most versatile applications.

New dobby of 3rd generation now available for water-jet applications

As a novelty, Stäubli will be presenting newly developed dobbies S3062/S3061 for water jet applications. These dobbies feature the sophisticated Stäubli rotation principle with high-end locking system of the 3rd Stäubli dobby generation. On the weaving machine they can be installed in high position with the new harness motions de82/83 for high-mounting, offering e.g. maintenance free bearings.

To complete the picture of Stäubli shedding systems, further upgraded dobbies as well as refined cam motions are being demonstrated at the booth.

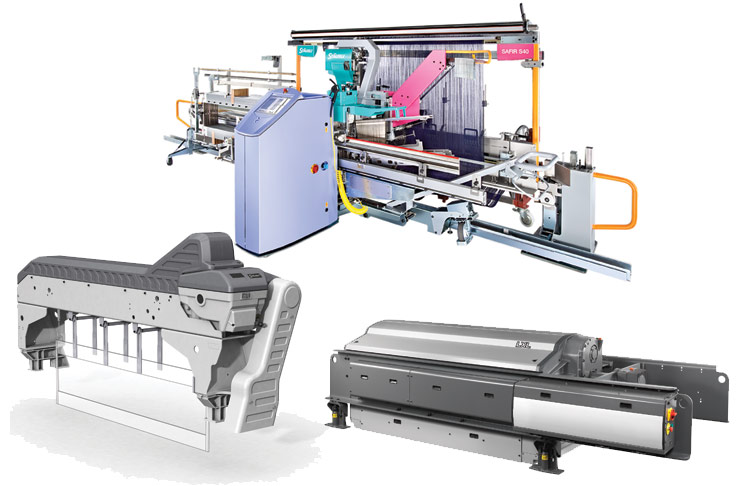

New automatic drawing-in machine SAFIR S40 for every weaving mill

The new mobile automatic drawing-in machine SAFIR S40, dedicated particularly to cotton weaves like denim and other standard fabrics, will be operating on the booth. With its unique and compact format it can fit in any traditional weaving mill. Like all of the SAFIR family members the S40 offers unequalled features like double end detection.

Schönherr carpet systems for most versatile woven carpets

At the Stäubli booth exclusive carpet samples woven on ALPHA 400 and 500 Series, some with the recently developed “Magic Shadow Effect” or the “Traditional Carpet Ef-fect”, can be seen.

DEIMO knitting solutions for a continuous sock production workflow

At the separate booth D15 in hall 4 Stäubli with its brand DEIMO is showing two circular sock knitting machines in operation, featuring the automatic toe-linking device D4S, and which is driven by the controller 2900 SL. Visitors can see as well a selection of electronic control solutions, input/output devices, and related programming tools mainly for the textile industry.

Stäubli Original Spare Parts

For easy ordering Stäubli offers an online spare parts ordering tool available 24h/d, 7d/week. An extract of original spare parts can be seen at the booth.

More Stäubli technology on partner’s booth

At numerous booths in the weaving hall visitors can see further Stäubli machinery. The Stäubli staff will inform about the concerned booth numbers and machinery details.