Asteks has developed CTA Apron Reinforced by Carbon for synthetics and blended fibres that has complicated spinning conditions and highly abrasive fibres such as PES, Lycra, Slub, Short staple Acrylic. This apron reinforced by carbon, the first in the world, has become an indispensable component for its users due to its longer working life time and incredible contribution to yarn quality.

Asteks, who has become the most important solution provider to spinning mills with its advanced roll shop equipment, continues to offer innovative products with intensive R&D and market studies. CTA Apron Reinforced by Carbon, the first in the world in the industry, proved to be successful with the fibres that have high complications in spinning with their sophisticated properties. Spinning mills and yarn producers are now increasing their productivity with CTA and are not worried about yarn quality under extreme conditions.

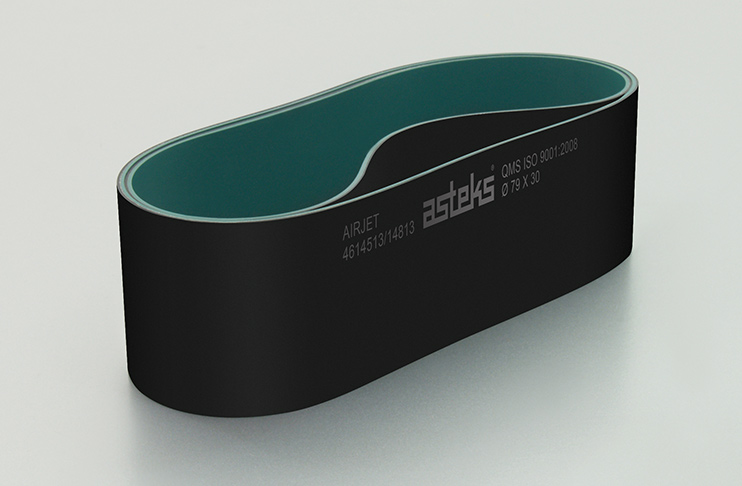

Asteks shows their strength as a partner to the customers by producing the apron, sleeves and grinding machines needed by spinning mills in European quality and safety standards. Developing innovative products for customers’ specific needs, Asteks has clearly responded to the request in longer-lasting apron for synthetic fibre spinning. The CTA Apron Reinforced by Carbon, which doubles the operation period comparing with the conventional aprons, is ahead of apron-welded yarn defects and has proved its remarkable success in the market in the short term. CTA, which is preferred by many Turkish spinning mills, represents Asteks’ commitment to innovation and customer satisfaction.

Tough conditions are not ‘Tough’ anymore

The first in the global textile industry, the CTA Apron Reinforced by Carbon have been specifically developed for the challenges that are not seen in the production of a standard yarn. These include working with synthetic fibres and synthetic blends, lycra and slub yarn production, and coarse count yarn production (towel and denim yarn). At all of these applications, due to the higher strength of fibre and its more aggressive structure, the aprons normally start wearing and tearing off , at relatively earlier stage. This phenomenon leads to yarn faults and higher ends-down.

The spinners either have to change this apron at short intervals or often have to produce defective yarn until they recognise the deformation. This causes the problems with the lower efficiency and inferior quality in the operation. Thanks to the special carbon reinforced exterior on the outer layer, the CTA, which lasts as twice long as the conventional aprons, allows the spinning under control in longer period and prevents the defects.

Fortified outer layer with carbon reinforcement, CTA is also resistant to compression, buckling and breakage at fibre lapping problems with its special middle layer. The structural knurled inner layer enhances gripping efficiency, which prevents dust and flies accumulations.

CTA has been developed upon market demand

Asteks Marketing and Sales Manager Sabri İlknur underlined that the CTA Apron Reinforced by Carbon have been developed upon the demands from the market. İlknur; “With our standard aprons and sleeves we have already become a well-known brand in spinning sector. However, we have seen the need for more specialized aprons for tougher working conditions, such as polyester and synthetic blends, lycra and slub yarns and coarse count yarns. We have developed the CTA by analysing our customers’ needs and difficulties. Our product, which has been in the market for last 3-4 years, has ended up the troubles of our customers with aprons in those tough conditions. We are very pleased with the returns we have received.”

The lifetime of CTA apron is 2 times higher

Stating that standard aprons are weak against aggressive fibres, Sabri Ilknur emphasized that the lifetime of CTA apron is 2 times higher than others. Pointing out on extension in the running life of the apron provides yarn manufacturers to relax a bit cost wise, İlknur said that keeping the yarn quality under control in a long course of a time has a direct effect on productivity. İlknur continued his words as;

“Compatible with all major brand spinning machines, CTA can provide up to 2 years of service life at synthetic fibres spinning. All spinning mills that have had trial with CTA, then decided to continue production with CTA. The comfort of reliability that CTA provides in complicated tough working conditions is the most attractive advantage for the customers. CTA is currently continues to work with its unrivalled performance in many highly demanding, tough conditions, in many regions of Turkey. We aim to make this product stronger both in the domestic and international market this year. As Asteks we show once again that we are an innovative and reliable partner in textile field with CTA.”

Customer experiences confirms on the success

Customer experience with CTA Apron Reinforced Carbon developed by ASTEKS reveals the success achieved;