The pick repair automation system PRA II Plus, used by Picanol to fully and automatically repair filling stops in airjet machines, makes it easy for weavers to detect late fillings and missing fillings. The system can repair filling stops up to 80 percent, stop the machine and perform the process for a time like 14 seconds. The PRA II Plus automatically restarts the machine after the filling stops, saving valuable time and resources without operator intervention required, while significantly reducing the risk of starting marks, allowing better fabric quality.

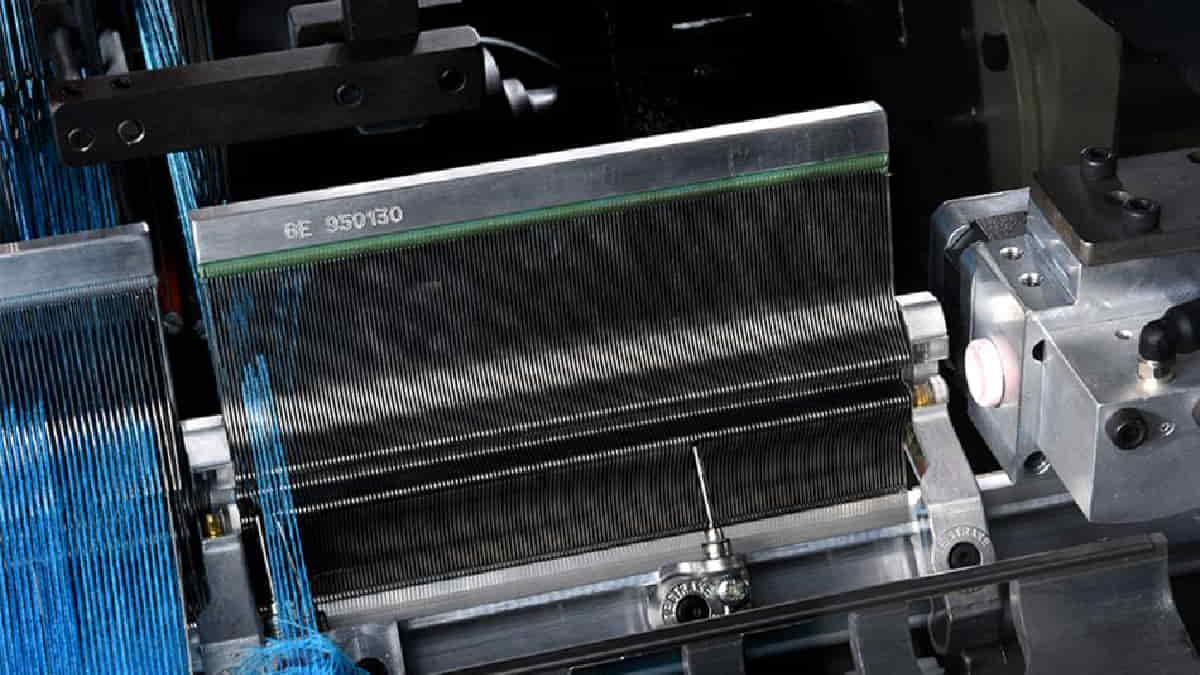

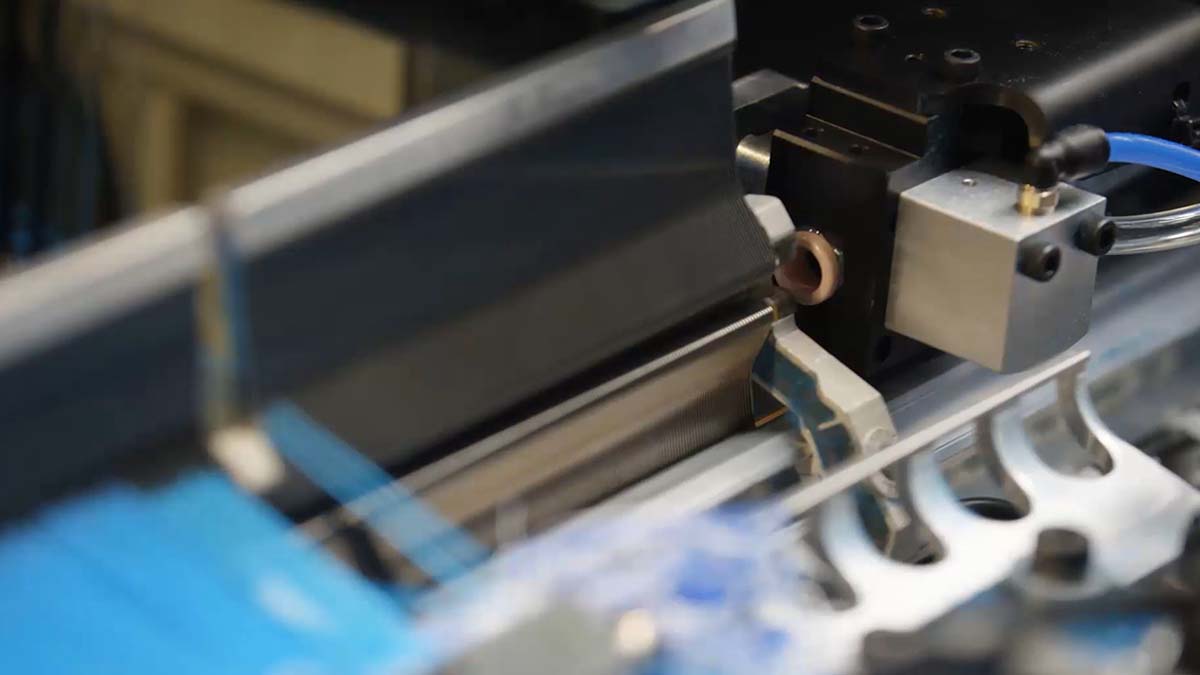

PRA II Plus, recognized as the fastest system in the market, provides a high success rate in filling cleaning processes. The PRA settings can be fine-tuned for each insertion channel individually, thus taking advantage of this feature even when using different types of filling yarn. The system, in which the weft is removed from the fabric pneumatically and mechanically, also minimizes the risk of partial fillings and start marks remaining in the shed, thanks to the right-hand extraction. The system does not require operator intervention, providing easy access for cleaning.

Filling cleaning in 14 seconds with PRA II Plus

The process takes 14 seconds in total and is automated from the stop of the weaving machine to the restart. First, the PRA sequence is activated after the machine detects late or missing fillings. During a short pause, the machine brings a filling end up to the right hand side suction mouth. After the filling arrives in the suction mouth and is detected, it is cut at the left-hand side of the machine. Then the filling end is completely removed by a clamp which is rotating and pneumatically controlled. The machine restarts itself after checking whether the filling has been removed successfully.

OmniPlus-i Connect airjet weaving machine combined with the new PRA II Plus system offers increased productivity not only in terms of success rate but also in terms of operating speed. Picanol offers weavers higher efficiency, performance and superior fabric quality in their machines in this way.