Using a novel fabrication process, MIT (Massachusetts Institute of Technology) researchers have produced smart textile that snugly conforms to the body so they can sense the wearer’s posture and motions. By incorporating a special type of plastic yarn and using heat to slightly melt it, a process called thermoforming, the researchers were able to greatly improve the precision of pressure sensors woven into multilayered knit textiles, which they call 3DKnITS. They used this process to create a ‘smart’ shoe and mat, and then built a hardware and software system to measure and interpret data from the pressure sensors in real-time. The machine-learning system predicted motions and yoga poses performed by an individual standing on the smart textile mat with about 99 percent accuracy.

A research assistant in the MIT Media Lab and lead author of a paper presenting 3DKnITS, Irmandy Wicaksono, saying that their fabrication process, which takes advantage of digital knitting technology, enables rapid prototyping and can be easily scaled up for large-scale manufacturing, explaines the process as follows:

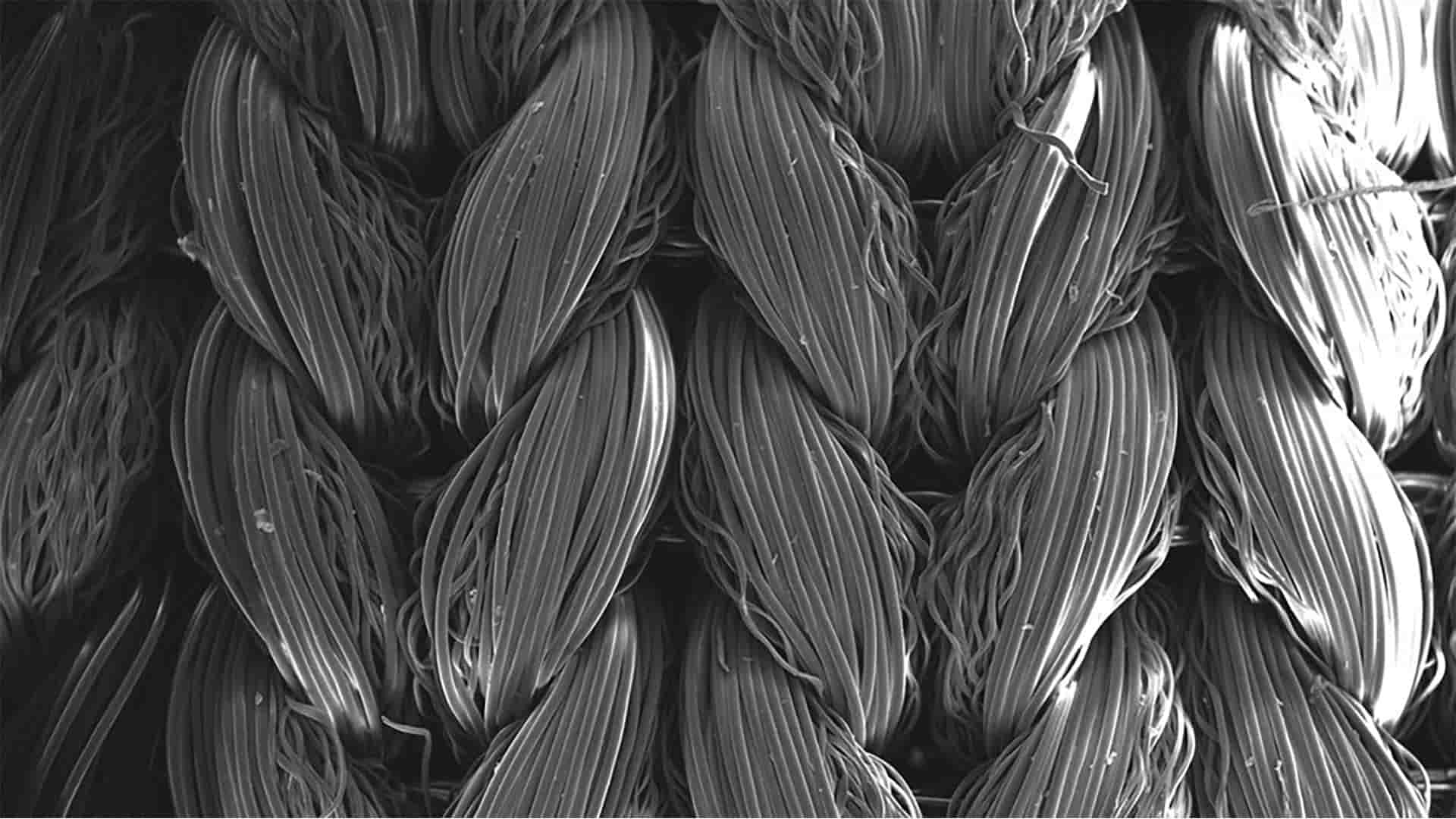

“To produce a smart textile, the researchers use a digital knitting machine that weaves together layers of fabric with rows of standard and functional yarn. The multilayer knit textile is composed of two layers of conductive yarn knit sandwiched around a piezoresistive knit, which changes its resistance when squeezed. Following a pattern, the machine stitches this functional yarn throughout the textile in horizontal and vertical rows. Where the functional fibers intersect, they create a pressure sensor.”

The smart textile offers new advantages, especially in health care and rehabilitation

The technique could have many applications, especially in health care and rehabilitation. For example, it could be used to produce smart shoes that track the gait of someone who is learning to walk again after an injury, or socks that monitor pressure on a diabetic patient’s foot to prevent the formation of ulcers. Irmandy Wicaksono discloses: “With digital knitting, you have this freedom to design your own patterns and also integrate sensors within the structure itself, so it becomes seamless and comfortable, and you can develop it based on the shape of your body.”

Wicaksono wrote the paper with MIT undergraduate students Peter G. Hwang, Samir Droubi, and Allison N. Serio through the Undergraduate Research Opportunities Program; Franny Xi Wu, a recent graduate of the Wellesley College; Wei Yan, Assistant Professor at the Nanyang Technological University; and senior author Joseph A. Paradiso, the Alexander W. Dreyfoos Professor and director of the Responsive Environments group within the Media Lab.