Operating in three main areas, connectors, robotics and textiles, Stäubli will exhibit its new weaving and knitting solutions at ITMA Asia + CITME on June 12-16. Participants will also have the opportunity to learn about how these solutions can improve weaving or sock knitting performance and overall mill efficiency.

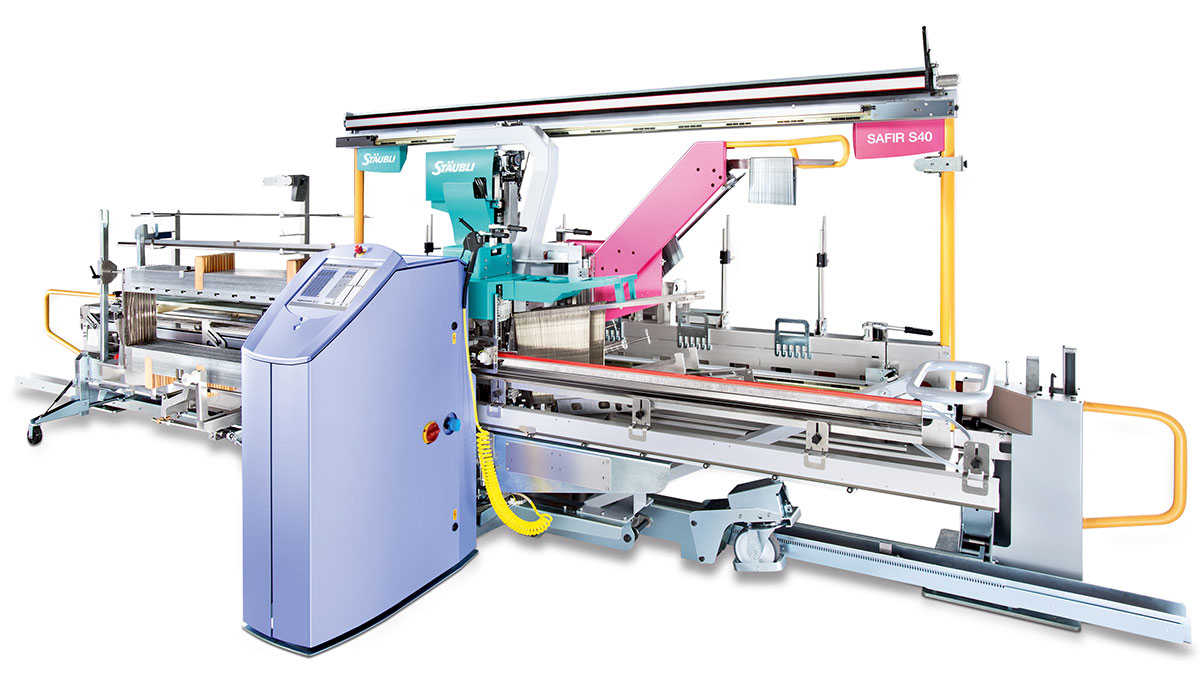

For an optimal weaving process, Stäubli offers solutions that meet many different prerequisites arising from upstream processes such as yarn processing and warp preparation. The SAFIR series drawing-in systems to be exhibited at the fair provide the user with important advantages such as the preparation of the best quality warps with perfectly aligned yarns. These are achieved with Stäubli’s exclusive yarn sorting technology AWC (Active Warp Control), which processes both single and multiple yarn types. Visitors to Stäubli’s booth C21 in hall 3 will be able to experience up close the innovations and how the technology of the SAFIR S40 automatic drawing-in machine enables greater high-quality output and supports on-time delivery as well.

Stäubli develops frame weaving solutions keeping their finger on the pulse of the market

Expanding its range of weaving and knitting solutions with its R&D studies, Stäubli responds to the growing market and customer demands. Stäubli frame weaving solutions are reliable for high-speed weaving and adaptable to any kind of plain or patterned fabric and any type of weaving machine. The broad range of 1600/1700 series of cam motions and S3000/S3200 series of electronic rotary dobbies have a long service life with their robustness and high quality. Besides, these machines are produced to high-quality standards and offer an ideal system together with dedicated maintenance-free Stäubli transmissions.

N4L jacquard machine at ITMA Asia for the first time

Stäubli offers users a wide range of electronic Jacquard weaving solutions, from large format machines (up to 25,600 hooks) to Jacquard machines for weaving brand on fabric and selvedges. The LXM Jacquard machine to be exhibited at the fair is available in two different formats, 2,688 and 5,376 hooks. Thus, it meets a wide range of application requirements while providing reliable operation at high weaving speeds.

The N4L Jacquard machine, which will be introduced by Stäubli for the first time in the Asian market, was developed to meet the growing demand for high-quality fabric and brand/name weaving on the fabric and selvedge. The machine enables quality brand/name weaving with easy handling, high availability and reduced maintenance needs.

ALPHA 500 series provides flexibility in carpet weaving

Regardless of the difficulty level in carpet weaving, the ALPHA 500 series of Schönherr carpet systems offer great flexibility in carpet weaving mills. This carpet weaving solution responds to rapidly changing market demands by providing the highest quality weaving in area rugs or wall-to-wall carpeting, low pile, lightweight loop, flat, cut pile or high density applications.

Quick toe-closing increases efficiency in sock knitting

Manufacturers who need to adjust quickly to market demands and meet tight delivery schedules gain significant advantages with the D4S toe-closing device. Toe-closing is a critical process in sock knitting and it takes a lot of time and plays a role in determining the quality. When the D4S toe-closing device is installed directly to the circular knitting machine, the device closes one sock while the machine is already knitting the next one.

In addition to offering many decisive functional advantages, Stäubli promises a very long lifespan for its machines, especially when using original replacement parts. The company provides the needs for replacement parts of its customers with the products it keeps in stock for years after the sale.